Automotive temperature sensor

Huaju Electronics can customize various high-quality automotive temperature sensors according to the different needs and requirements of customers. The automotive temperature sensors produced by Huaju Electronics are mainly used in automotive air conditioners, engine oil temperatures, automotive water temperatures, and automotive seat temperatures. Fuel temperature, evaporator fin temperature, exhaust pipe temperature, automobile motor temperature, electric vehicle power battery temperature, transmission oil temperature, intake pipe temperature and other temperature detection,

- Commodity name: Automotive temperature sensor

- 产品描述

- 产品规格及参数

-

NTC (negative temperature coefficient) thermistor is a heat-sensitive semiconductor resistor. Its resistance value decreases as the temperature increases. The temperature coefficient of resistance is in the range of -2%/k~-6%/k, which is about that of metal. 10 times the temperature coefficient of resistance. Changes in the resistance value of the NTC thermistor can be caused by changes in the external ambient temperature, or can be caused by self-heating due to the flow of current. His various uses are based on this property. NTC thermistors are constructed from polycrystalline ceramics with mixed oxides. The conductive mechanism of this material is quite complex.

Huaju Electronics is an early professional manufacturer of NTC thermistors in China. The NTC thermistors produced by the company are widely used in various handheld devices and miniaturized electronic equipment. They are also widely used in various temperature measurement and temperature compensation occasions. Relying on its technical advantages in the field of thermistors, Huaju Electronics produces temperature sensor products with stable performance and reasonable prices. The products are widely used in military, medical, human life, industrial automation, automobiles, security and fire protection, home appliances, communications, etc. Fields and occasions that require temperature measurement or overheating protection. NTC temperature sensors are usually composed of 2 or 3 metal oxides, mixed in a popular clay, and sintered into a dense sintered ceramic in a high-temperature furnace. Oxygen-bonded metals tend to donate free electrons. Ceramics are generally excellent insulators. But this is only theoretically the case with thermistor-type ceramics when the temperature is close to absolute zero. However, as the temperature increases to more common ranges, thermal excitations throw out more and more free electrons. As many electrons carry current through the ceramic, the effective resistance decreases. Resistance changes extremely sensitively with temperature. Typical changes are (-)7[%] to 3[%] reduction per degree Celsius. This is the most sensitive of any sensor suitable for use over a wide temperature range. The rated room temperature resistance depends on the resistivity, size and geometry of the base material, and the contact area of the electrodes. A thermistor that is thick and narrow has a relatively high resistance, while a thermistor that is thin and wide has a lower resistance. Actual sizes are also very flexible, they can be as small as .010 inches or very small in diameter. There is almost no limit to the maximum size, but half an inch or less usually applies.

Temperature sensor structure:

NTC thermistor, probe assembly (combination). A finished thermistor assembly (combination) composed of a thermistor shell, extension lead, and sometimes a connector.

structure

Generally composed of NTC thermistor, probe (metal shell or plastic shell, etc.), extension lead, and metal terminal or connector

.principle

Using NTC thermistor, under a certain measurement power, the resistance value decreases rapidly as the temperature rises. Utilizing this characteristic, the NTC thermistor can be used to determine the corresponding temperature by measuring its resistance value, thereby achieving the purpose of detecting and controlling temperature.

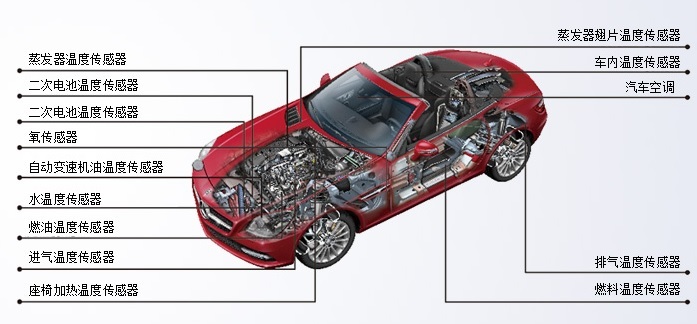

Application of NTC temperature sensor in automobiles

The function of the temperature sensor is to measure the temperature of the engine's intake air, cooling water, fuel, etc., and convert the measurement results into electrical signals and transmit them to the ECU. For all gasoline engine electronic control systems, the intake air temperature and cooling water temperature are controlled by the ECU The two necessary temperature parameters, while other temperature parameters vary with the type of electronic control system and control needs.

The intake air temperature sensor is usually installed in the air flow meter or in the intake duct or air flow meter from the air filter to the throttle body. The water temperature sensor is arranged in an appropriate position on the engine cooling water line, cylinder head or body. .Sensors that can be used to measure temperature include wire-wound resistance type, diffusion resistance type, semiconductor transistor type, metal core type, thermocouple type and semiconductor thermistor type. They are currently used for intake air temperature and cooling water temperature. The most widely used in measurement is the thermistor temperature sensor.

Huaju Electronics can customize various high-quality automotive temperature sensors according to the different needs and requirements of customers. The automotive temperature sensors produced by Huaju Electronics are mainly used in automotive air conditioners, engine oil temperatures, automotive water temperatures, and automotive seat temperatures. Fuel temperature, evaporator fin temperature, exhaust pipe temperature, automobile motor temperature, electric vehicle power battery temperature, transmission oil temperature, intake pipe temperature and other temperature detection,

Working principles and types of commonly used temperature sensors in automobiles

Temperature is an important parameter that reflects the thermal load status of the engine. In order to ensure that the control system can accurately control the operating parameters of the engine, the engine coolant temperature, intake air temperature and exhaust temperature must be monitored at any time in order to correct the control parameters, calculate the mass flow rate of the air sucked into the cylinder, and perform exhaust purification processing.

The coolant temperature sensor (Coolant Temperature Sensor, CTS), usually called the water temperature sensor, is installed on the engine coolant outlet pipe. Its function is to detect the temperature of the engine coolant and convert the temperature signal into an electrical signal and transmit it to the ECu. The ECU corrects the injection time and ignition time according to the engine's temperature signal, so that the engine can operate in optimal conditions.

The Intake Air Temperature Sensor (IATS) is installed in the intake pipe. Its function is to detect the intake air temperature and convert the temperature signal into an electrical signal and transmit it to the ECU. The intake air temperature signal is a correction signal for various control functions. If the signal from the intake air temperature sensor is interrupted, it will cause difficulty in hot starting and increase exhaust gas emissions.

As we all know, air weight is related to intake air temperature and atmospheric (inlet air) pressure. When the inlet air temperature is low, the air density is high, and the weight of the same volume of gas increases; conversely, when the inlet air temperature increases, the weight of the same volume of gas will decrease. In fuel injection systems that use manifold pressure type, vane type, Kalman vortex type, and core type air flow sensors, since the air flow measured by the air flow sensor is volume flow, it is necessary to equip an intake air temperature sensor and an atmospheric pressure sensor. Pressure Sensor. The ECU corrects the fuel injection amount based on the engine's intake air temperature and pressure signals, allowing the engine to automatically adapt to changes in external ambient temperature (cold, high temperature) and pressure (plateau, plain). When the intake air temperature is low (air density is high), the resistance of the thermistor is large, the signal voltage input from the sensor to the ECU is high, and the ECU controls the injector to increase the amount of fuel injection; conversely, when the intake air temperature is high (air density is low) ), the resistance of the thermistor is small, and the signal voltage input by the sensor to the ECU is low, the ECU will control the injector to reduce the amount of fuel injection.

There are many types of temperature sensors, the commonly used ones are thermistor type, metal thermal resistance type, wire wound resistor type, transistor type, etc. Thermistors can be divided into positive temperature coefficient (Positive Temperature Coefficient, PTC) thermistors, negative temperature coefficient (NTC) thermistors, critical temperature thermistors (critical Temperature Resistor, CTR) and Linear thermistor. Commonly used thermistors include negative temperature coefficient type and positive temperature coefficient type. Cars commonly use NTC thermistor temperature sensors, such as coolant temperature sensor (CTS), intake air temperature sensor (IATS), exhaust temperature sensor (Ex-haust Air Temperature Sensor, EATS), fuel temperature sensor (FuelTemperature Sensor) , FTs) etc.

Application of NTC temperature sensor in automotive electronics

In power electronics, thermal monitoring and thermal management are very important. Temperature sensors are mainly used in battery management systems, motor control and motors. The battery management system can monitor the voltage, current and temperature of the battery to gain a detailed understanding of the battery's condition, and at the same time control the charge and discharge balance and charge and discharge control of individual battery units to ensure the safe use of the battery and at the same time slow down the life of the battery. attenuation.

Application of NTC temperature sensor in automotive electronics

The measurement of voltage and current is relatively simple, but the measurement of temperature is relatively complicated. The battery designs used by different customers will vary, so different batteries have different hotspot distributions and different mechanical structures. The temperature sensor must be closely integrated with the hot spot of the object being measured to accurately measure the temperature of the hot spot. Therefore, the temperature sensor design of the battery management system needs to consider fast and accurate temperature measurement, and the structure and installation method need to be considered to ensure Good heat conduction in the automotive environment and hot spots, and at the same time, it must meet the reliability and life requirements in the automotive environment.

The motor is the core component that converts electrical energy into kinetic energy in new energy vehicles. The power levels of hybrid vehicles and electric vehicles/buses range from 10KW to 200KW. By monitoring the temperature of the motor, the motor controller can adopt different control strategies in different states to protect the entire power unit. The internal structure of the motor is very compact, so miniaturization, high temperature requirements, resistance to harsh electromagnetic interference, and high reliability are requirements for motor sensors. Huajue Electronics has various motor temperature sensors that can meet the product requirements of ultra-thin, high temperature, high reliability and high accuracy of hybrid power systems.

6. Main technical parameters

Nominal resistance

B value

dissipation coefficient

Thermal time constant

Operating temperature

R25(KΩ)

A(25/50℃)K

(mW/℃) (S)

(℃)

B(25/85℃)K

1 3270A For type 1 package ≥2.0

For type 2 package ≥4.0For type 1 package ≤15

For type 2 package ≤70-55~+125℃ Can be customized if you have special requirements

1 3950A 2 3470A 2 4000A 2 3930A 2 3483A 2.252 3935A 2.55 3740A 3 3950A 4.7 3470A 4.7 3950A 5 3270A 5 3380A 5 3470A 5 3600A 5 3950A 6.8 3977A 6.8 4200A 8 3780A 10 3270A 10 3435B 10 3470A 10 3600A 10 3950A 10 3977B 10 4100A 15 3680A 15 3950A 15 4100A 15 4150A 20 3950A 20 4150B 20 4200A twenty three 3950A twenty three 4200A 30 3899A 30 3950A 30 4200A 40.27 3900A 40.27 3979B 40 3950A 47 3950A 47 3990A 47 4150A 49.12 3979B 50 3950A 50 3990A 50 4050A 50 4150A 100 3950A 100 3990A 100 400A 100 4050A 100 4150A 100 4200A 100 4250A 100 4450A 150 4370B 150 4500A 200 4250A 470 4450A Note:

·Fill in the sensor package form code and size in the first box; fill in the nominal resistance value in the second box; fill in the nominal resistance value accuracy code in the third box. ·When the accuracy of the nominal resistance value is ±1%, the corresponding error of the B value is ±1%, and the errors of the other B values are ±2%.

·In addition to the above specifications, our company can also supply products according to the special requirements of users.

·For temperature sensors with a temperature measurement range exceeding 150°C, special instructions are required. The company's temperature sensor can reach a maximum temperature of 250°C.

Key words:

Automotive temperature sensor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!