Motor PTC thermal protection temperature sensor

For mechanical and electrical equipment such as lathes, electric ovens, mushroom machines, and other unattended equipment that require continuous operation during production, accidents caused by motor overheating or temperature control failure are common. Using PTC thermistors for motor overheating protection can effectively prevent them. Accidents happen. A common method for protecting motors from overheating is to bury extremely small sensors with PTC thermistor temperature sensing heads in the windings of the motor stator. Under normal circumstances, the PTC thermistor used for motor overheating protection is in a low resistance state and does not affect the performance of the motor. normal operation.When the inside of the motor overheats due to a fault, the PTC thermistor used for motor overheat protection undergoes a sudden change in thermal resistance, and the relay associated with it loses power and is released, and the motor stops running and waits for the fault to be eliminated before it can start running again. The advantage of this protection method is to directly monitor the temperature changes inside the winding, so that the motor can be protected before the overheating temperature breaks through the insulation level of the motor. At the same time, due to the recoverability of the TC thermistor, there is no need to replace it with a new one like a fuse resistor.

- Commodity name: Motor PTC thermal protection temperature sensor

- 产品描述

- 产品规格及参数

-

For mechanical and electrical equipment such as lathes, electric ovens, mushroom machines, and other unattended equipment that require continuous operation during production, accidents caused by motor overheating or temperature control failure are common. Using PTC thermistors for motor overheating protection can effectively prevent them. Accidents happen. A common method for protecting motors from overheating is to bury extremely small sensors with PTC thermistor temperature sensing heads in the windings of the motor stator. Under normal circumstances, the PTC thermistor used for motor overheating protection is in a low resistance state and does not affect the performance of the motor. normal operation.When the inside of the motor overheats due to a fault, the PTC thermistor used for motor overheat protection undergoes a sudden change in thermal resistance, and the relay associated with it loses power and is released, and the motor stops running and waits for the fault to be eliminated before it can start running again. The advantage of this protection method is to directly monitor the temperature changes inside the winding, so that the motor can be protected before the overheating temperature breaks through the insulation level of the motor. At the same time, due to the recoverability of the TC thermistor, there is no need to replace it with a new one like a fuse resistor.

product description

Product Overview of PTC Thermistors for Overheating Protection

SCRBH temperature-controlled PTC thermistor utilizes the characteristic that the resistance value of the PTC thermistor rises suddenly above the Curie temperature. When the ambient temperature rises abnormally, the protection circuit equipped with the PTC thermistor changes in resistance value. Connect or disconnect the circuit to protect the components.

Main parameters of SCRBH temperature control PTC thermostor

Protection temperature point TS(℃)

Rated zero power resistance value R25 (Ω)

Resistance value at protection temperature (Rs, Min)

Protection temperature -15℃ Resistance value (RS-15, Max)

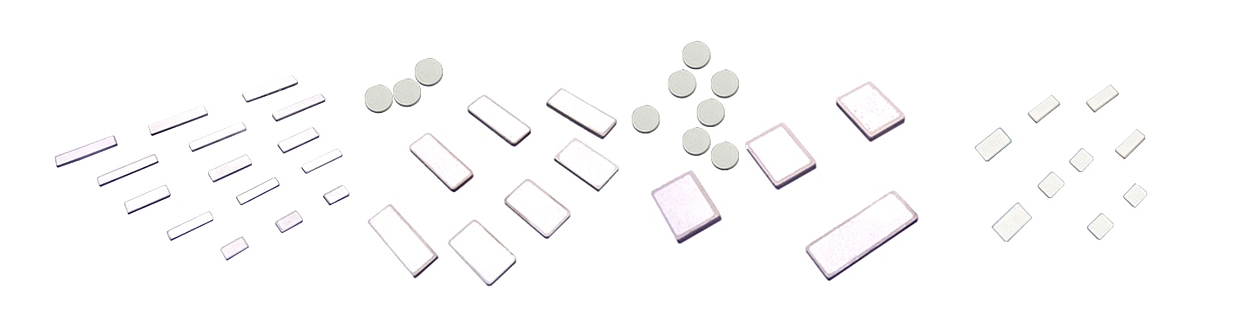

1. SCRBH temperature-controlled PTC thermistor series products are divided into two shapes: A-lead type, B-surface mount type

2. Protection temperature range: 60~130℃

3. Fast response time

4. Long-term stability

5. Small size and easy installation

6. No further settings are required after the product is overheated. 3. Model name, appearance, structure and dimensions:

DJRBH motor protection PTC thermistor

Application scope:

This product is widely used in situations where over-temperature protection is required. When the product is installed in equipment that requires over-temperature protection, the PTC resistance signal is transmitted to the motor protector. When the temperature approaches the insulation heat-resistant grade, the motor protector disconnects the circuit to implement protection.

Features:

Made of ultra-small PTC thermistor, it has small size, long life, good stability and high sensitivity. The technical indicators have reached the international level of similar products.

use

It can be used alone or in series to control the temperature at different points in the same circuit.

Technical data

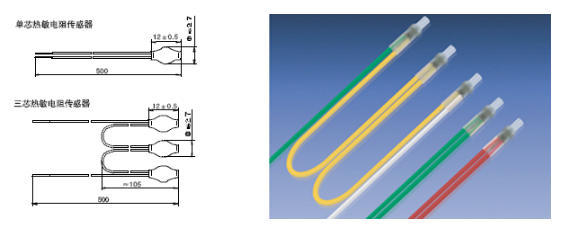

The control temperature range is Tk60℃~Tk180℃. The control temperature Tk is set to a specification every 5°C. One to six cores can be produced according to user requirements. The SCRBHC series adopts German DIN 44080, DIN 44081, and DIN 44082 standards.

naming method:

E: 1 temperature sensing head Z: 2 temperature sensing heads D: 3 temperature sensing heads V: 4 temperature sensing heads S: 6 temperature sensing heads

Standard lead length DS: 520 200 200 520 DK 520 520 (unit: mm)

Regular model:

PTC thermistor parameter data ES series (single core) DS series (three cores) unit Maximum working voltage Umax 25

25

V

Rated operating temperature tk 60~180

60~180

℃

Tk tolerance ±5

±5

℃

Repeatability of Tk ΔT ±0.5

±0.5

℃

Rated resistance value R25℃±1℃ ≤100

≤300

Ω

Lower limit temperature control point (V≤2.5V) TK-5(℃) ≤550

≤1650

Ω

Upper limit temperature control point (V≤2.5V) TK+5(℃) ≥1330

≥3990

Ω

Protection temperature +15℃ resistance value TK+15(℃) ≥4

≥12

KΩ

Thermal response time Ts ≤5

≤5

S

Insulation withstand voltage V 2.5

2.5

KV

Wire pull Withstand 10N, 10S pulling force without damage.

Withstand 10N, 10S pulling force without damage.

N

Maximum storage temperature TLmax 160

160

℃

minimum storage temperature TLmin -25

-26

℃

working principle

PTC thermistor has positive temperature coefficient resistance characteristics. When the temperature reaches its Curie point, the phase change of the semiconductor ceramic begins, and its resistance value increases rapidly with the increase of temperature. The change is especially obvious near the control temperature point Tk, thus serving the purpose of controlling the circuit.

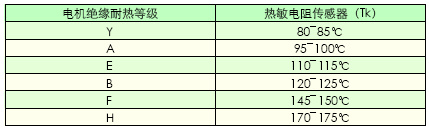

It is recommended to use the thermistor sensor according to the following table (for reference only)

Control the lead color corresponding to the temperature

protection temperature 30 40 50 60 70 80 90 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 180 Thread color Brown Brown Brown white white white green red orchid Brown orchid Ash red orchid red white white black orchid orchid orchid white white Thread color black red Ash Ash Brown white green red Ash Brown green Ash green orchid black orchid black black black red Brown green red Hua Ju Temperature Sensor Co., Ltd. overheat protection type PTC thermistor and Murata overheat protection type PTC thermistor interchange comparison table

Huajuan EPCOS model KRIWAN model DJRBH-60-ES B59100M1060A070 01 D 116 DJRBH-70-ES B59100M1070A070 01 D 117 DJRBH-80-ES B59100M1080A070 01 D 118 DJRBH-90-ES B59100M1090A070 01 D 119 DJRBH-100-ES B59100M1100A070 01 D 200 DJRBH-110-ES B59100M1110A070 01 D 210 DJRBH-120-ES B59100M1120A070 01 D 220 DJRBH-130-ES B59100M1130A070 01 D 230 DJRBH-140-ES B59100M1145A070 01 D 240 DJRBH-145-ES B59100M1140A070 01 D 245 DJRBH-150-ES B59100M1150A070 01 D 250 DJRBH-155-ES B59100M1155A070 01 D 255 DJRBH-160-ES B59100M1160A070 01 D 260 DJRBH-170-ES B59100M1170A070 01 D 270 DJRBH-180-ES B59100M1180A070 01 D 280 DJRBH-060-DS B59300M1060A070 01 D 456 DJRBH-070-DS B59300M1070A070 01 D 457 DJRBH-080-DS B59300M1080A070 01 D 458 DJRBH-090-DS B59300M1090A070 01 D 459 DJRBH-100-DS B59300M1100A070 01 D 460 DJRBH-110-DS B59300M1110A070 01 D 461 DJRBH-120-DS B59300M1120A070 01 D 462 DJRBH-130-DS B59300M1130A070 01 D 463 DJRBH-140-DS B59300M1140A070 01 D 468 DJRBH-145-DS B59300M1145A070 01 D 464 DJRBH-150-DS B59300M1150A070 01 D 469 DJRBH-155-DS B59300M1155A070 01 D 465 DJRBH-160-DS B59300M1160A070 01 D 470 DJRBH-170-DS B59300M1170A070 01 D 466 DJRBH-180-DS B59300M1180A070 01 D 467 Installation instructions:

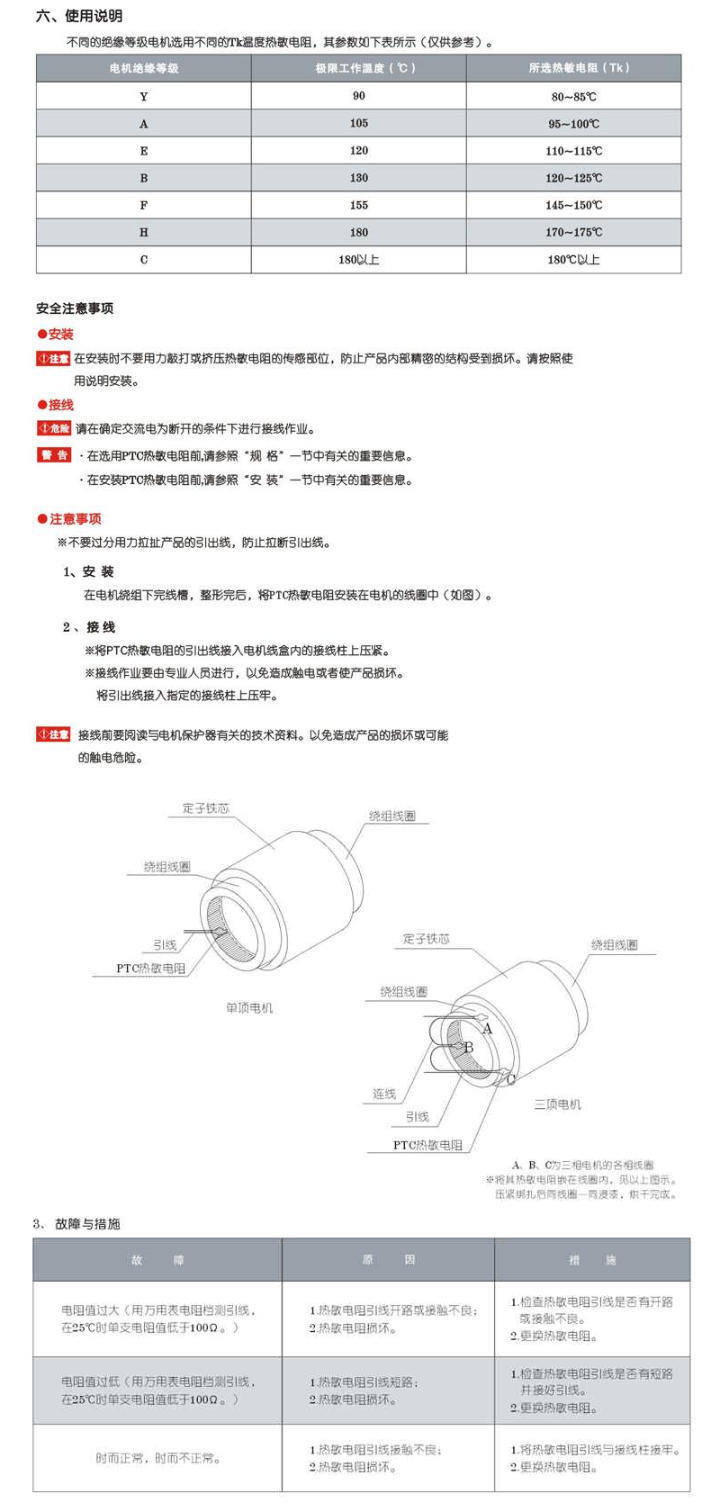

Fix the sensor at the location where the temperature needs to be detected (usually installed in the winding). Do not knock or squeeze the sensor chip hard during installation. Do not let the lead bear tensile force. The lead is connected to the motor junction box. It must be used in conjunction with a motor protector to control motor over-temperature.

Each chip of the three-core sensor is installed at an appropriate position in the three-phase winding, with one core installed in each phase winding.

Motor PTC temperature sensor overheat protection module

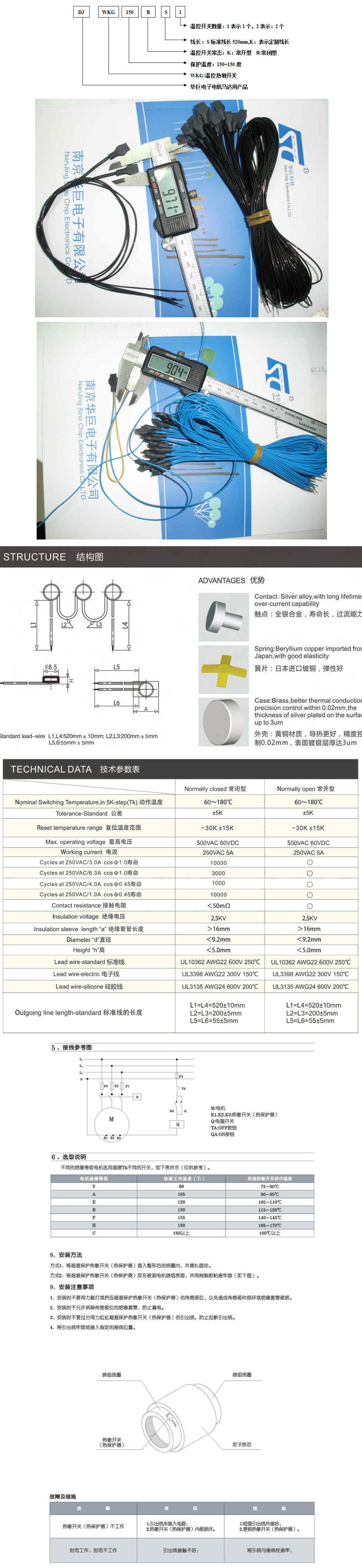

Naming rules:

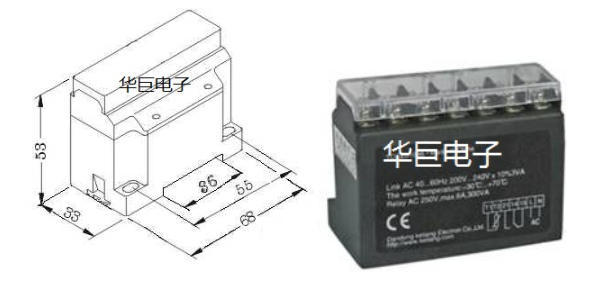

Dimensions

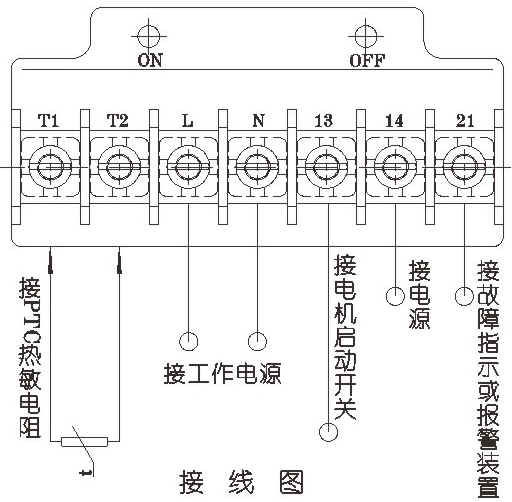

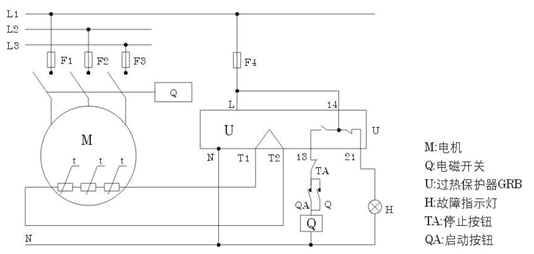

Wiring diagram

Technical Parameters

Operating Voltage 24(Vac/Vdc) 110Vac 220Vac Power frequency 47~63Hz Power consumption <1VA contact current 6A/250VAC (resistive) Working relative humidity 5%~95% Working temperature -20℃~65℃ storage temperature -25℃~70℃ Transport temperature -25℃~70℃ The number of thermistors that can be connected in series 1-9 only Action resistance single Double three 1KΩ×(1±10%) 2KΩ×(1±10%) 3KΩ×(1±10%) Recovery resistance single Double three 500Ω~600Ω 1KΩ~1.2KΩ 1.5KΩ~1.8KΩ Installation method Guide rail/fixing hole PTC temperature control module operating temperature

Thermistor temperature control point PTC temperature control module action resistance PTC temperature control module restores resistance value PTC temperature control module operating temperature PTC temperature control module restores temperature TK single two three single two three TK to TK+5℃ TK to TK-5℃ 1KΩ×(1±10%) 2KΩ×(1±10%) 3KΩ×(1±10%) 500Ω~600Ω 1KΩ~1.2KΩ 1.5KΩ~1.8KΩ Reference wiring diagram: Take three series connections as an example

Motor overheating protection temperature switch:

DJWKG series temperature-controlled thermal switch (thermal protector) is a temperature-controlled switch specially used for motor overheat protection. This series of thermal switches are mainly suitable for industrial motor products, for motor under-voltage, over-voltage, overload, etc . Faults are reflected in the motor coil temperature, so DJWKG series thermal switches are ideal thermal sensor components for motor protection.

Features:

The DJWKG series temperature-controlled thermal switch (thermal protector) is small in size, sensitive in action, and reliable in performance. Its various indicators have reached the international advanced level. However, when the motor encounters a rapidly changing thermal overload, it cannot protect the motor.

Key words:

Motor PTC thermal protection temperature sensor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!