Chip varistors for automotive LED lights

As a new green lighting technology, high-power white LED has the advantages of high light conversion efficiency, low energy consumption, long life and no maintenance, and is gradually being used in various lighting fields. The long life of LED is based on its safe working environment. For LED lighting, there are two main threats that affect its life: one is overcurrent shock, which means that the current applied to the LED exceeds the maximum rated current in the LED technical data sheet. , including overcurrent shock caused by overvoltage; the other is overheating damage. These damages can manifest as immediate failure of the device, or may occur long after the overcurrent surge event, shortening the working life of the LED.

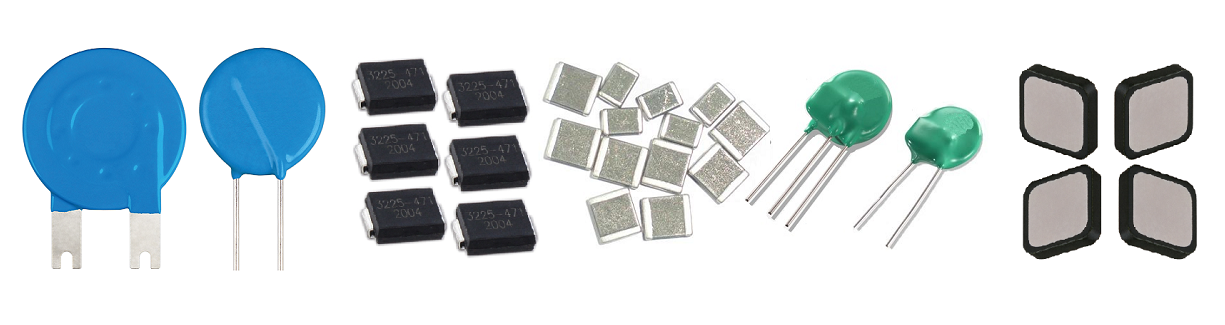

- Commodity name: Chip varistors for automotive LED lights

- 产品描述

- 产品规格及参数

-

As a new green lighting technology, high-power white LED has the advantages of high light conversion efficiency, low energy consumption, long life and no maintenance, and is gradually being used in various lighting fields. The long life of LED is based on its safe working environment. For LED lighting, there are two main threats that affect its life: one is overcurrent shock, which means that the current applied to the LED exceeds the maximum rated current in the LED technical data sheet. , including overcurrent shock caused by overvoltage; the other is overheating damage. These damages can manifest as immediate failure of the device, or may occur long after the overcurrent surge event, shortening the working life of the LED.

Causes of damage to LED lamps

The failure of LED lamps is caused by the failure of the power supply and driver, and the failure of the LED device itself. Usually the damage to LED power supplies and drivers comes from overcurrent surge (EOS) of the input power supply and circuit breakage at the load end. Overcurrent surges from the input power supply often cause damage to the driver chips in the driver circuit, as well as breakdown damage to passive components such as capacitors. A short-circuit fault at the load end may cause over-current driving of the drive circuit, and the drive circuit may be damaged by short-circuit or overheating damage caused by the short-circuit fault. The failure of the LED device itself mainly occurs in the following situations.

1. Transient overcurrent event

A transient overcurrent event means that the current flowing through the LED exceeds the maximum rated current in the LED technical data sheet. This may be caused directly by large current or indirectly by high voltage, such as transient lightning strikes and switching power supply transients. Overcurrent caused by overvoltage events such as state switching noise and power grid fluctuations. These events are transient and of very short duration, and we usually call them spikes, such as "current spikes" and "voltage spikes". Situations that cause transient overcurrent events also include transient overcurrent when the LED is powered on or plugged in and out while powered.

For LED lighting in automobiles, the ISO7637-2 transient load dump surge impact is an important threat to its normal operation.

The failure mode of LED after being subjected to overcurrent shock is not fixed, but usually results in damage to the welding wire, as shown in Figure 1. This damage is usually caused by extremely large transient overcurrents. In addition to causing the welding wire to burn out, it may also cause damage to other parts close to the welding wire, such as sealing materials.

3. Model name, appearance structure and dimensions:

2. Electrostatic discharge events

Electrostatic discharge (ESD) damage is the most common transient overvoltage hazard in the manufacturing, transportation and application of highly integrated semiconductor devices, and LED lighting systems must meet the "human body electrostatic discharge mode" of the IEC61000-4-2 standard. 8kV contact discharge to prevent the system from overcurrent shock failure that may be caused by electrostatic discharge.

The performance of the LEDPN junction array will be reduced or damaged, as shown in Figure 2. The internal failure of the LED chip caused by the discharge path of the ESD event may only cause partial functional damage, but in severe cases, it may also cause permanent damage to the LED.

For LED lighting designs where nearly 80% of energy is converted into heat, thermal management and fault overheat protection are a challenge. Both theory and practice have proven that the performance and life of LEDs are closely related to the operating temperature of the PN junction of the LED. When the junction temperature in the LED chip increases by 10°C, the luminous flux will be attenuated by 1%, and the LED life will be reduced by 50%.

For LED lighting in automobiles, the ISO7637-2 transient load dump is an important threat to its normal operation. The failure mode of LEDs after being subjected to overcurrent shock is not fixed, but usually results in damage to the welding wires. This kind of damage is usually caused by extremely large transient overcurrent. In addition to causing the welding wire to burn out, it may also cause damage to other parts of the welding wire, such as sealing materials. Generally, in order to suppress the load-off voltage of the generator, an overvoltage protector is connected in parallel to the power input end of the ECU.

Huaju Electronics relies on its years of accumulation in the field of overvoltage protection and advanced technology to develop a full range of overvoltage protectors suitable for the automotive industry. It uses advanced nano-ceramic material processing technology to make the product's reliability performance particularly outstanding. It exhibits better characteristics than TVS or varistor currently used on the market.

characteristic:

1. Comply with AEC-Q200 REV-C standard

2. Provide the function of withstanding the highest level of voltage suppression in ISO-7637-2 load dump (Load Dump)

3. Comply with ROHS, HF, REACH environmental standards

4. It has good high temperature characteristics. (-40℃~125℃)

5. It has extremely low leakage current characteristics. (<1 uA)

6. With two-way suppression function

model Operating Voltage Varistor voltage Maximum limit voltage Maximum circulation load dump Jump Start Voltage(5 Min) Vdc V(1mA) V A W LD (J) 10 times Vjump(V) SCSMD1206A240-1R5J 12 24(±10%) 40 400 1.5 24.5

SCSMD1206A240-030J 12 24(±10%) 40 400 3 24.5 SCSMD1206A240-060J 12 24(±10%) 40 500 6 24.5

SCSMD1210A240-030J 12 24(±10%) 40 800 3 24.5 SCSMD1210A240-060J 12 24(±10%) 40 800 6 24.5

SCSMD1210A240-120J 12 24(±10%) 40 1000 12 24.5 SCSMD1812A240-060J 12 24(±10%) 40 1600 6 24.5

SCSMD1812A240-120J 12 24(±10%) 40 1600 12 24.5 SCSMD1812A240-250J 12 24(±10%) 40 2000 25 24.5

SCSMD2220A240-120J 12 24(±10%) 40 3000 12 24.5 SCSMD2220A240-250J 12 24(±10%) 40 3000 25 24.5

SCSMD2220A240-500J 12 24(±10%) 40 5000 50 24.5 SCSMD2220A470-250J twenty four 47(±10%) 77 3000 25 45.0 SCSMD2220A470-500J twenty four 47(±10%) 77 4000 50 45.0 Main manufacturer specifications

car factory Ud Ri (internal resistance) Td Puls Recommended specifications Ω GMW3097 34V 2 400ms 10 times SCSMD1206A240-030J Q/CA-F01-0300(FAW) 21.5V 1 400ms 10 times SCSMD1206A240-030J MGR ES:62.21.627(SAIC) 18.5V 2 250ms 10 times SCSMD1206A240-1R5J TL82466(Volkswagen) 42V 4 300ms 10 times SCSMD1206A240-060J Load Dump - refers to the disconnection of the alternator during the process of charging the battery; in addition, load dump will also occur at the moment the car engine is started, which is the largest energy conductivity in the entire vehicle. interference pulse. The reason is that when the generator is working, the heavy load is suddenly thrown away (such as the charging battery). This is because the energy on the generator inductance is instantly released nowhere, which will produce a hundreds of voltages in the power supply circuit. Volts, the rising edge is generally (5~10ms) and the half-peak width is approximately (100, 200, 300, 400, etc., depending on the power of the generator)

Key words:

Chip varistors for automotive LED lights

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!