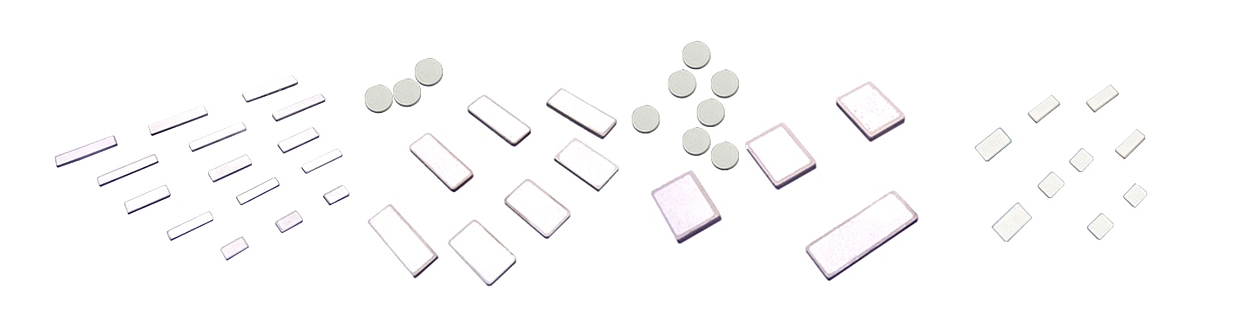

Contact arc extinguishing, relay contactor contact arc extinguishing module

Breakdown occurs between electrodes in absolute vacuum. The electrons that create the arc originate from the material of the contact itself. The temperature at which arcing occurs depends on the work function of the contact material. Considering work function issues, tungsten and molybdenum are often used as contact materials. Work function refers to the maximum insulating electrostatic field that a certain contact air gap can withstand. Note that during the switching of thermal environments, when the contact air gap shrinks to zero, the arc will be pulled out and the electrostatic field intensity increases. Therefore, as the contacts gradually close, the electrostatic field at some points will be very high enough to breakdown the gap.

- Commodity name: Contact arc extinguishing, relay contactor contact arc extinguishing module

- 产品描述

- 产品规格及参数

-

Contact arc extinguishing, relay contactor contact arc extinguishing module introduction:

Breakdown occurs between electrodes in absolute vacuum. The electrons that create the arc originate from the material of the contact itself. The temperature at which arcing occurs depends on the work function of the contact material. Considering work function issues, tungsten and molybdenum are often used as contact materials. The work function refers to the maximum insulating electrostatic field that a certain contact air gap can withstand. Note that during the switching of thermal environments, when the contact air gap shrinks to zero, the arc will be pulled out and the electrostatic field intensity increases. Therefore, as the contacts gradually close, the electrostatic field at some points will be very high enough to break down the gap.

Arc hazards

Common DC large-load DC motors, DC clutches, and self-flow solenoid valves. When these inductive load switches are turned off, there will be hundreds or even thousands of volts of back electromotive force, causing surges and arcs that will reduce the life of the contacts or even completely damage. If the current is small, such as around 1A, the back electromotive force will cause arc discharge. The discharge will cause metal oxides to contaminate the contacts, causing the contacts to fail, the contact resistance to increase, and sometimes the arc generated will even damage the relay contacts. The melting causes the contacts to stick together, causing the circuit that should be disconnected to fail, causing great harm to the equipment and even causing it to be scrapped. In response to the above problems, Huaju Electronics launched the composite PTC thermistor module WMZ13A-75E0610D431VT, which is used to solve the arc extinguishing of contact arcs, which effectively solves the problem of arc extinguishing of relay contacts.

1. Due to the influence of reverse electromotive force, the voltage applied to both ends of the relay or thyristor will reach 5-10 times the normal voltage at the moment the relay or thyristor contact is disconnected. This voltage will ionize the air at the moment the contact is disconnected to form HNO3, which will easily corrode the metal material or cause the thyristor to be broken down, directly affecting its service life. The use of this model of product has a better control effect on the arcing of relay contacts.

2. Composite PTC thermistor is currently the best way to extinguish arc when used in relay contacts. It can effectively reduce the micro-on current during charging and discharging of the resistor-capacitor circuit, and can also reduce the impact of a single varistor on the contact. point of residual voltage drop to achieve better protection effect. Nanjing Huaju Electronics grandly launches PTC composite thermistor with contact arc extinguishing.

Key words:

Contact arc extinguishing, relay contactor contact arc extinguishing module

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!