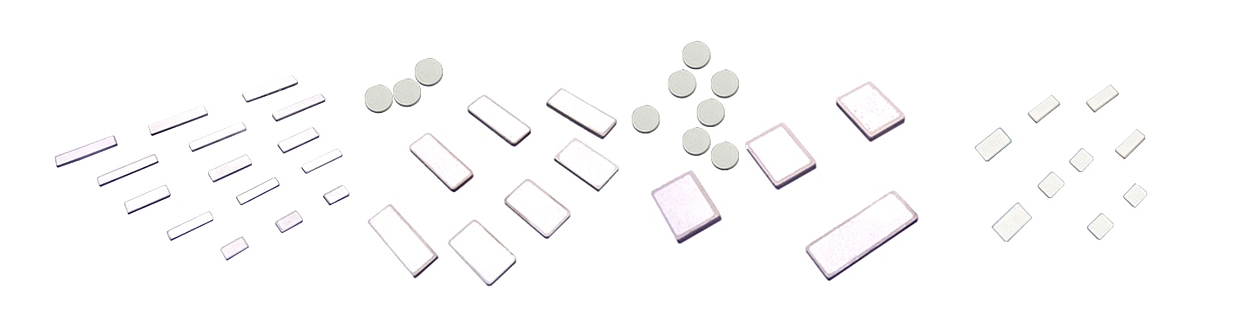

Shell-mounted compressor starting PTC thermistor

This product has the characteristics of no contact, low noise, high reliability, long life, etc. Different characteristics and structures are used to ensure different machine design requirements.

- Commodity name: Shell-mounted compressor starting PTC thermistor

- 产品描述

- 产品规格及参数

-

Product name: Compressor starting PTC thermistor

Delay start type PTC thermistor

Application principles

When starting, the motor must overcome its own inertia and the reaction force of the load (for example, the refrigerator compressor must overcome the reaction force of the refrigerant when starting). Therefore, the motor requires large current and torque when starting. When the rotation is normal, in order to save energy, the required torque will be significantly reduced. Add a set of auxiliary coils to the motor, which only works when starting, and disconnects when normal. This effect can be achieved by connecting the PTC thermistor in series to the starting auxiliary coil. After starting, the PTC thermistor enters a high resistance state and cuts off the auxiliary coil.

This product has the characteristics of no contact, low noise, high reliability, long life, etc. Different characteristics and structures are used to ensure different machine design requirements.

1. PTC thermistor for starting the compressor of the refrigerator

The compressor of the refrigerator is driven by a single phase induction motor. When the motor starts, it must overcome both its own inertia and the reaction force of the load-high-pressure refrigerant. It needs to ensure a large starting current. For this reason, a starting circuit with a PTC thermistor is usually used (schematic diagram See Figure 1).

2. PTC thermistor for starting variable frequency air conditioner

When the inverter air conditioner starts, the voltage is added to the rectifier and filter circuit through the PTC component, charging the capacitor smoothly to the set value. The power module IPM starts to work, inverting the input DC voltage into three AC currents and adding them to the three-phase AC motor windings. , so that the motor can operate normally. At the same time, after the capacitor is charged to the set value, the DC voltage is output through the IPM to the relay pull-in switch K, and the PTC element is terminated and the work is suspended (see Figure 2).

The purpose of connecting PTC components in series in the main circuit is to prevent the rectifier and filter circuit from directly bearing the impact of large current during the initial power-on period, causing damage to the energy storage components. That is, the PTC component plays a buffering and protective role in the early stage of power-on. In addition, if the relay fails (cannot close normally), the PTC element will become a high resistance state after being energized, which can protect the circuit.

3. Model naming:

Application circuit schematic diagram

2: Test circuit

model

modelNominal resistance

switching temperature maximum voltage Maximum current Start Time Power consumption Recovery Time Coil resistance

R25(Ω) Tb(℃) Vmax(V) Imax(A) T0(S) Pmax(W) Trmax() Rref(Ω) WMZ92-10RM220 10 120±10 220 9 0.4-2.0 5 120 25 WMZ92-15RM250 15 250 8 0.4-2.0 5 120 25 WMZ92-22RM300 twenty two 300 7 0.4-2.0 5 120 25 WMZ92-33RM350 33 350 6 0.4-2.0 5 120 30 WMZ92-40RM300 40 300 5 0.2-1.5 4 120 25 WMZ92-47RM400 47 400 5 0.2-1.5 4 100 25 WMZ92-101RM500 100 500 4 0.2-1.5 4 100 10 WMZ92-15RM250 15 130±10 250 8 0.4-2.0 5 100 15 WMZ92-22RM300 twenty two 300 7 0.4-2.0 5 100 25 WMZ92-33RM350 33 350 6 0.2-2.0 5 100 25 WMZ92-47RM250 47 250 5 0.2-2.0 5 100 25 WMZ92-33RM250 33 120±10 250 4.5 0.1-0.5 2.3 80 30 WMZ92-40RM250 40 250 4 0.1-0.5 2.3 80 30 WMZ92-47RM250 47 250 4 0.1-0.5 2.3 80 30

Key words:

Shell-mounted compressor starting PTC thermistor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!