PTC heating piece heats PTC thermistor

WMZ5 constant temperature heating PTC thermistor has constant temperature heating characteristics. The principle is that after the PTC thermistor is powered on, it self-heats and the resistance value enters the transition zone. The surface temperature of the constant temperature heating PTC thermistor will maintain a constant value. This temperature is only related to The Curie temperature of PTC thermistor is related to the applied voltage and has basically nothing to do with the ambient temperature.

- Commodity name: PTC heating piece heats PTC thermistor

- 产品描述

- 产品规格及参数

-

Product name: WMZ5 constant temperature heating PTC thermistor

Constant temperature heating type PTC thermistor

WMZ5 constant temperature heating PTC thermistor has constant temperature heating characteristics. The principle is that after the PTC thermistor is powered on, it self-heats and the resistance value enters the transition zone. The surface temperature of the constant temperature heating PTC thermistor will maintain a constant value. This temperature is only related to The Curie temperature of PTC thermistor is related to the applied voltage and has basically nothing to do with the ambient temperature.

PTC heater is a heating device designed using the constant temperature heating characteristics of PTC thermistor. In small and medium power heating situations, PTC heater has constant temperature heating, no open flame, high heat conversion rate, minimal influence on power supply voltage, and long natural life. With advantages that traditional heating elements cannot match, their application in electric heating appliances is increasingly favored by R&D engineers.

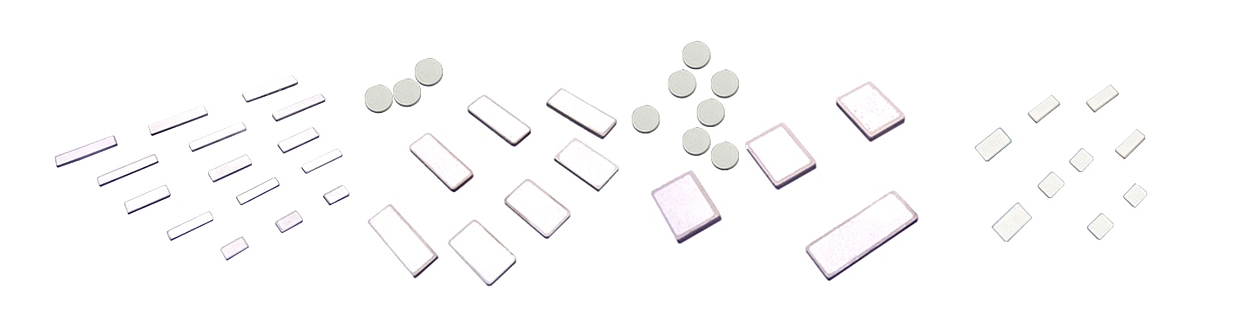

Constant temperature heating PTC thermistors can be made into a variety of shapes and structures and different specifications. Common ones include disc shape, rectangle, strip shape, ring shape, honeycomb porous shape, etc. The above-mentioned PTC heating elements and metal components can be combined to form Various forms of high-power PTC heaters

PTC heaters are classified according to structural characteristics

(1) WMZ5 ordinary and practical PTC ceramic heater. This type of appliance mainly includes: electric mosquito repellent, hand warmer, dryer, electric hot plate, electric iron, electric soldering iron, electric bonding device, curling iron, etc. .It is characterized by low power, but high thermal efficiency and very practical.

(2) WMZ5 automatic constant temperature PTC heater. This type of equipment mainly includes: small crystal device constant temperature bath, constant temperature incubator, electronic thermos flask, insulation box, thermos cup, thermos plate, thermos cabinet, thermos table, etc. It is characterized by automatic heat preservation, simple structure, good constant temperature characteristics, high thermal efficiency, and wide operating environment temperature range.

(3) Hot air PTC heater. This type of hot air PTC heater mainly includes: small warm air heater, hair dryer, room heater, dryer, drying cabinet, clothes dryer, industrial drying equipment, etc. Its characteristic is the output The hot air has high power, fast heating, safety, and can automatically adjust the air temperature and power consumption.

3. Model naming:

Customize various shapes of PTC heating resistors, PTC heating sheets, PTC heating sheets, heating PTC thermistors

Model naming:

model

switching temperature

surface temperature

Rated zero power resistance

Rated voltage

maximum voltage

Overall dimensions (mm)Tc(℃)

Tsurf(℃)R25(Ω)

U(V)

Vmax(V)A±1B±0.1C±0.2WMZ5-D08100□X030 100 110 10 twenty four 30 8 1.5 WMZ5-D08102□P3BB 30 50 1000 240 270 8 3 WMZ5-D08102□X1BB 110 130 1000 240 270 8 2.3 WMZ5-D08180□X030 100 110 18 twenty four 30 8 1.5 WMZ5-D10102□XDBB 135 155 1000 240 270 10 2.3 WMZ5-D10102□XGBB 165 180 1000 240 270 10 2.3 WMZ5-D10180□X060 100 110 18 43 60 10 2.3 WMZ5-D10201□X5BB 150 170 200 220/240 270 10 2.3 WMZ5-D10301□X6AA 160 175 300 110 140 10 2.3 WMZ5-D10501□X3BB 130 150 500 240 270 10 2.3 WMZ5-D10501□X7BB 170 185 500 240 270 10 2.3 WMZ5-D10501□XDBB 135 155 500 240 270 10 2.3 WMZ5-D13102□PFBB 55 75 100 240 270 13 2.3 WMZ5-D13150□PG60 65 75 15 42 60 13 1.5 WMZ5-D13152□YBBB 215 230 1500 240 270 13 2.5 WMZ5-D13152□YDBB 235 250 1500 240 270 13 2.5 WMZ5-D13360□X430 140 150 36 twenty four 30 13 1.3 WMZ5-D13680□XE60 145 155 68 42 60 13 1.3 WMZ5-D14501□XHBB 175 190 500 220/240 270 14 2.4 WMZ5-D17150□X560 150 160 15 42 60 17 1.4 WMZ5-D20102□X1BB 110 130 1000 240 270 20 2.3 WMZ5-D20102□X4BB 140 160 1000 240 270 20 2.3 WMZ5-D20362□YDBB 235 250 3600 240 270 20 2.5 WMZ5-D203R6□X760 170 180 3.6 42 60 20 1.4 WMZ5-RA1181□P7AA 70 90 180 100/120 140 16 11 2.5 WMZ5-RA1301□P7AA 70 85 300 100/120 140 16 11 2.5 WMZ5-RA1701□P8BB 80 100 700 220/240 270 16 11 2.5 WMZ5-RA2301 Y3AA 230 250 300 100/120 140 23.5 10 2.2 WMZ5-RA2501□P9BB 90 110 500 220/240 270 23.5 10 2.2 WMZ5-RA2701 Y4BB 240 255 700 220/240 270 23.5 10 2.2 WMZ5-RA3801 Y1BB 210 230 800 220/240 270 19 12 2.2 WMZ5-RA4501 Y4BB 240 255 500 220/240 270 36 6 2.3 WMZ5-RA5102 Y6BB 260 275 1000 220/240 270 twenty four 15 2.2 Other specifications and sizes

surface temperature Operating Voltage Overall dimensions (mm) Commonly used resistance values

Tsurf(℃) U(Vac)

diameter thickness R25(Ω)

300 220 19 2.1 2.5-4000 240 220 13 3 1-4 220 220 8 3 2.5-5500 205 220 8 3 0.8-2000 180 220 8 3 1-8000 175 220 12 3 1100-2900 160 220 8 3 1-8000 70 220 8 3 2-4500 180 24Vdc 13 3 50-100 220 12Vdc 13 3 5-50 108 12Vdc 13 3 50-150 220 12Vdc 12 1.2 6-12 220 5Vdc 13 1.8 5-15 twenty two 5Vdc 13 1.8 5-10 PTC heating element for thermostat Features: Surface brushed silver electrode, excellent electrode contact performance, high temperature accuracy, small power aging, long service life

surface temperature Withstand voltage Dimensions Commonly used resistance values

Tsurf(℃) U(Vac)

(mm) R25(Ω)

95 450 10*2.8*2.0 1000-5000 100 600 4.9*3.9*1.5 3000-8000 120 450 3.6*2.0*1.1 1500-4500 125 450 10*2.8*2.0 200-1000 135 450 13*2.8*2.0 1000-4000 155 600 4.9*3.9*1.5 3000-8000 155 450 13*2.8*2.0 1000-7000 160 450 Φ8*2 3000-8000 165 450 10*2.8*2.0 500-2000 180 450 5.8*5.8*2.0 2000-6000 180 500 13*2.8*2.0 1000-4000 180 450 10*2.8*2.0 2000-6000 180 600 4.9*3.9*1.5 3000-8000 180 450 Φ8*2 3000-8000 200 450 10*2.8*2.0 1000-6000 200 450 2.3*2.3*1.35 1500-4500 210 450 12.8*2.8*2.0 1000-4000 215 450 Φ6.5*2 500-1500 220 450 5.8*5.8*2.0 2000-6000 240 450 10*2.8*2.0 2000-6000 240 450 13*2.8*2.0 500-1500 240 450 5.8*5.8*2.6 2000-6000 240 48Vdc 10*2.8*2.0 25-80 245 600 4.9*3.9*1.5 3000-8000 260 450 10*2.8*2.0 1000-4000 260 450 5.8*5.8*2.0 2000-6000 Features of PTC heating elements for air conditioners: fully inspected withstand voltage, high reliability, low power aging, and long service life.

Curie temperature Withstand voltage Dimensions Commonly used resistance values

Tc(℃) U(Vac)

(mm) R25(Ω)

150 800 24*15*2.4 800-5000 175 800 24*15*2.4 800-5000 200 800 24*15*2.4 800-5000 220 700 32*12*2.4 800-5000 220 700 24*15*2.4 800-5000 220 850 24*15*3.0 800-5000 230 700 32*12*2.4 800-5000 250 700 32*12*2.4 800-5000 250 700 24*15*2.4 800-5000 250 850 24*15*3.0 800-5000 260 700 32*12*2.4 800-5000 260 700 24*15*2.4 800-5000 260 850 24*15*3.0 800-5000 PTC heating element for electric vehicles Features: high withstand voltage, high reliability, small power aging

Curie temperature Withstand voltage Overall dimensions (mm) Commonly used resistance values

Tc℃) U(Vdc)

Length*width or diameterΦ R25(Ω)

204 1050 24*15*3.0 2000-10000 204 1200 24*15*3.5 3000-30000 204 1300 24*15*4.0 5000-40000 204 1200 35*12*3.5 3000-30000 204 1300 35*10*4.0 5000-40000 204 1300 35*15*4.0 5000-40000 220 1050 24*15*3.0 2000-10000 220 1200 24*15*3.5 3000-30000 220 1300 24*15*4.0 5000-40000 220 1200 35*12*3.5 3000-30000 220 1300 35*10*4.0 5000-40000 220 1300 35*15*4.0 5000-40000 240 1050 24*15*3.0 2000-10000 240 1200 24*15*3.5 2000-10000 240 1300 24*15*4.0 5000-40000 240 1200 35*12*3.5 3000-30000 240 1300 35*10*4.0 5000-40000 240 1300 35*15*4.0 5000-40000 250 1050 24*15*3.0 2000-10000 250 1200 24*15*3.5 3000-30000 250 1300 24*15*4.0 5000-40000 250 1200 35*12*3.5 3000-30000 250 1300 35*10*4.0 5000-40000 250 1300 35*15*4.0 5000-40000 Product features of electric mosquito coils: high temperature accuracy, good voltage resistance reliability, excellent voltage impact resistance and mechanical impact resistance.

surface temperature Withstand voltage Overall dimensions (mm) Commonly used resistance values

Tsurf(℃) U(Vac)

Length*width or diameterΦ R25(Ω)

70 600 Φ8*3 2000-4500 90 500 10*2.8*2.0 1000-4000 100 500 12*4*2.3 1250-3750 175 600 Φ12*3 1100-2900 180 500 12*6*2.3 1250-3750 205 600 Φ8*3 825-2175 210 500 Φ9*2.5 1200-3500 214 600 Φ8*3 2500-5500 220 600 Φ8*3 2500-5500 220 600 Φ12*3 1100-2900 220 500 Φ12*2.5 1200-3500 330 48Vdc Φ12*1.2 6-12 PTC heating element for hair curlers and hair straighteners. Features: high temperature accuracy, good voltage resistance and reliability, and full specifications.

Curie temperature Operating Voltage Withstand voltage Overall dimensions (mm) Commonly used resistance values

Tc(℃) U(Vac)

U(Vac) Length*width or diameterΦ R25(Ω)

150 110/220 330/600 35*6*2.0 200-3000 150 110/220 330/600 36*8*2.0 200-3000 150 110/220 330/600 30*10*2.0 200-3000 150 110/220 330/600 35*10*2.0 200-3000 150 110/220 330/600 30*15*2.0 200-3000 150 110/220 330/600 35*13*2.0 200-3000 150 110/220 330/600 35*15*2.0 200-3000 180 110/220 330/600 35*6*2.0 200-3000 180 110/220 330/600 36*8*2.0 200-3000 180 110/220 330/600 30*10*2.0 200-3000 180 110/220 330/600 35*10*2.0 200-3000 180 110/220 330/600 30*15*2.0 200-3000 180 110/220 330/600 35*13*2.0 200-3000 180 110/220 330/600 35*15*2.0 200-3000 200 110/220 330/600 35*6*2.0 200-3000 200 110/220 330/600 36*8*2.0 200-3000 200 110/220 330/600 30*10*2.0 200-3000 200 110/220 330/600 35*10*2.0 200-3000 200 110/220 330/600 30*15*2.0 200-3000 200 110/220 330/600 35*13*2.0 200-3000 200 110/220 330/600 35*15*2.0 200-3000 230 110/220 330/600 35*6*2.0 200-3000 230 110/220 330/600 36*8*2.0 200-3000 230 110/220 330/600 30*10*2.0 200-3000 230 110/220 330/600 35*10*2.0 200-3000 230 110/220 330/600 30*15*2.0 200-3000 230 110/220 330/600 35*13*2.0 200-3000 230 110/220 330/600 35*15*2.0 200-3000 258 110/220 330/600 35*6*2.0 200-3000 258 110/220 330/600 36*8*2.0 200-3000 258 110/220 330/600 30*10*2.0 200-3000 258 110/220 330/600 35*10*2.0 200-3000 258 110/220 330/600 30*15*2.0 200-3000 258 110/220 330/600 35*13*2.0 200-3000 258 110/220 330/600 35*15*2.0 200-3000 272 110/220 330/550 35*6*2.0 200-3000 272 110/220 330/550 36*8*2.0 200-3000 272 110/220 330/550 30*10*2.0 200-3000 272 110/220 330/550 35*10*2.0 200-3000 272 110/220 330/550 30*15*2.0 200-3000 272 110/220 330/550 35*13*2.0 200-3000 272 110/220 330/550 35*15*2.0 200-3000 290 110/220 330/500 35*6*2.0 200-3000 290 110/220 330/500 36*8*2.0 200-3000 290 110/220 330/500 30*10*2.0 200-3000 290 110/220 330/500 35*10*2.0 200-3000 290 110/220 330/500 30*15*2.0 200-3000 290 110/220 330/500 35*13*2.0 200-3000 290 110/220 330/500 35*15*2.0 200-3000 Small household appliances use PTC heating elements. Features: high withstand voltage, high reliability, small power aging

Curie temperature Operating Voltage Withstand voltage Overall dimensions (mm) Commonly used resistance values

Tc(℃) U(Vac)

U(Vac) Length*width or diameterΦ R25(Ω)

258 110/220 650 24*15*2.4 1000-4000 258 110/220 650 35*15*2.4 1000-4000 272 110/220 600 24*15*2.4 1000-4000 272 110/220 600 35*15*2.4 1000-4000 290 110/220 550 24*15*2.4 1000-4000 290 110/220 550 35*15*2.4 1000-4000 Note: PTC heating sheets, PTC heating sheets, PTC heaters, PTC heating elements, and PTC heating rods are customized products and can be customized according to customer requirements. Thank you.

Key words:

PTC heating piece heats PTC thermistor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!