LED constant current temperature compensation thermistor

WMZL is specially developed for LED constant current compensation. It can replace LED constant current diodes and has a high cost performance. It is a perfect alternative to LED constant current diodes.

- Commodity name: LED constant current temperature compensation thermistor

- 产品描述

- 产品规格及参数

-

Use thermistor to create a cheap LED constant current source solution

WMZL is specially developed for LED constant current compensation. It can replace LED constant current diodes and has a high cost performance. It is a perfect alternative to LED constant current diodes.

The WMZL series is a temperature compensation resistor specially designed for LED lighting. It adopts the thermistor compensation method as an LED constant current source. It has a simple circuit, good reliability, easy combination, economical and practical, and is suitable for various LED headlights, fluorescent lamps, street lamps; vehicles and ships. Lights, solar LED garden lights; LED displays, etc. require constant current. It is specifically aimed at the decrease in the LED PN junction voltage VF caused by temperature in LED lighting, that is, -2mV/℃, which is called the negative temperature effect of the PN junction. This characteristic is a fatal flaw in lighting applications, directly affecting the luminous efficiency, luminance, and chromaticity of LED devices. For example, the optimal operating current of LED is 20mA at room temperature of 25℃. When the ambient temperature rises to 85℃, the PN junction voltage VF decreases and the operating current increases sharply to 35mA~37mA. At this time, the increase in current will not increase the brightness. , called brightness saturation. What's more serious is that the rise in temperature causes the spectral wavelength to shift, causing chromatic aberration. Working in this high temperature zone for a long time will also cause the device to age and the luminous brightness to gradually decay. Similarly, when the ambient temperature drops to -40°C, the junction voltage VF increases, the optimal operating current will decrease from 20mA to 8mA~10mA, and the luminous brightness will also decrease with the decrease of the current, which cannot reach the illumination required in the application site. .

In order to avoid the shortcomings caused by the above characteristics, the following measures are usually adopted for LED lamp-related products: 1. Install the LED on a heat sink, or use a fan to cool down. 2. The LED adopts the power supply mode of constant current source, which will not increase the regenerative current due to the rise of LED temperature, and prevent the PN junction from viciously heating up. Or use both methods together. Practice has proven that these two methods are used for high-power LED lights (such as advertising background lights, street lights). It is indeed an effective measure. But when LED lights enter ordinary people's homes, they encounter the following problems: Can the heat sink and air cooling be integrated in the space of an ordinary lamp head? If a constant current source circuit composed of integrated circuits or many components is used, its lifespan will not be taken into account. For LED, it depends on a certain "short board" of the entire system; whether there is an eye-catching price. Using the thermistor compensation method to solve the problem of LED constant current source is both economical and practical.

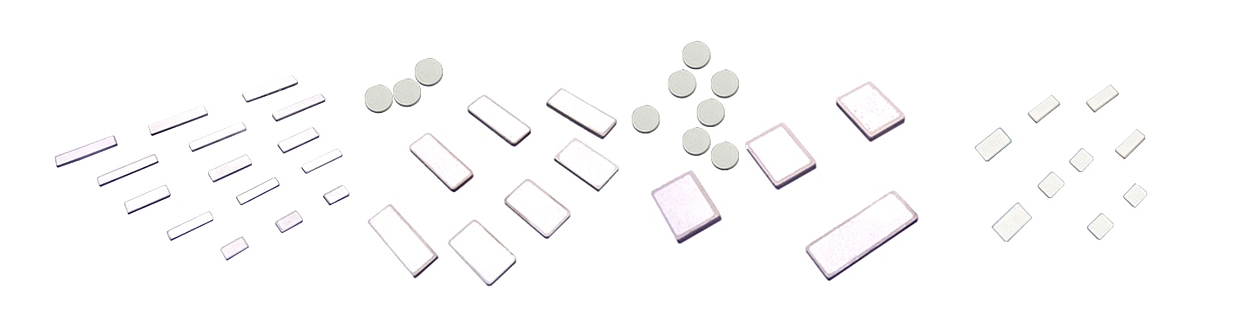

3. Model name, appearance structure and dimensions:

Taking a 20mA LED as an example, the comparison curve between the LED constant current compensation resistor without LED constant current compensation resistor and the LED compensation resistor with LED compensation resistor is shown in I without LED constant current compensation resistor and II with LED compensation resistor installed.

model encapsulation

constant current The optimal number of compensations Compensation resistor rated voltage drop Best cell voltage Maximum withstand voltage Dimensions Rated resistance (mA) Recommended compensation amount Vr Column (mm) R25(Ω) WMZL-5A20-□ A 20 4~7 3 3+VLEDX(4~7) 15V Φ1.3X2.7 150 WMZL-10A20-□ A,B 20 8~14 6 6+VLEDX(8~14) 30V Φ1.7X5.2 300 WMZL-45A20-□ A 20 40~45 10 10+VLEDX(40~45) 75V Φ2.5X8.0 500 WMZL-45A15-□ A 15 40~45 11.3 11.3+VLEDX(40~45) 75V Φ2.5X8.0 750 WMZL-5A30-□ A 30 4~7 3 3+VLEDX(4~7) 15.0V Φ1.3X2.7 100 WMZL-10A30-□ A,B 30 8~14 6 3+VLEDX(8~14) 30.0V Φ1.7X5.2 200 WMZL-5B100-□ A,B 100 1 0.65 0.65+VLED 3.0V Φ1.7X5.2 6.5 WMZL-C300-□ A,B 300 1 0.5 0.5+VLED 1.5V Φ1.7X5.2 1.7 WMZL-C350-□ A,B 350 1 0.5 0.5+VLED 1.5V Φ1.7X5.2 1.4 The unit operating voltage needs to be basically consistent with the power supply voltage. If the power supply voltage has been determined, you can select the VLED value of the LED, or increase or decrease the number of LEDs to match the voltage. Unit operating

voltage = thermistor voltage drop + VLED Only, the working voltage after series connection = 3V + 3.0V × 7 = 24V Example: The power supply is 24V, C350 6 pieces in series 1W/350mA/3.1V//LED 7 pieces in series, the working voltage = 0.5V × 6 + 3.1V × 7 =24.7V power supply choose 24v, C350 6 pcs in series 1w/350mA/3.5V/LED 6 pcs in series working voltage = 0.5V×6+3.5V×6=24V

Key words:

LED constant current temperature compensation thermistor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!