Inverter energy storage capacitor surge suppression self-restoring PTC thermistor

High-voltage and large-capacity energy storage capacitors are widely used in industrial products. Due to the characteristic that the voltage across the capacitor cannot change suddenly, at the moment the system is turned on, the current flowing into the capacitor from the grid energy often reaches a peak level of hundreds of amperes. Such a high The startup current seriously threatens the rectifier devices and overcurrent fuses in the circuit, and also brings great harmonic pollution to the public commercial power grid. Therefore, almost all circuits are equipped with a "start-up surge suppression circuit" to suppress the startup surge current to a reasonable level.

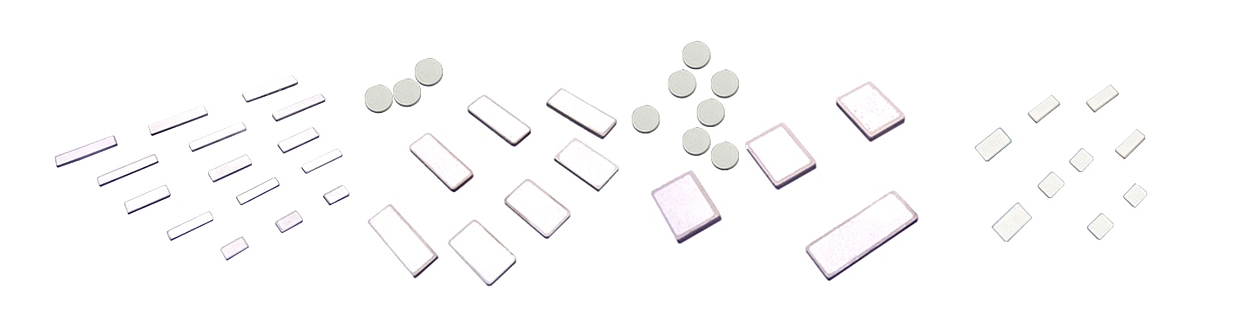

- Commodity name: Inverter energy storage capacitor surge suppression self-restoring PTC thermistor

- 产品描述

- 产品规格及参数

-

1. Application scope:

High-voltage and large-capacity energy storage capacitors are widely used in industrial products. Due to the characteristic that the voltage across the capacitor cannot change suddenly, at the moment the system is turned on, the current flowing into the capacitor from the grid energy often reaches a peak level of hundreds of amperes. Such a high The startup current seriously threatens the rectifier devices and overcurrent fuses in the circuit, and also brings great harmonic pollution to the public commercial power grid. Therefore, almost all circuits are equipped with a "start-up surge suppression circuit" to suppress the startup surge current to a reasonable level.

The traditional "surge suppression component" is a common fixed resistance "cement resistor". Especially in products with power above kilowatts, high-power "cement resistors" are commonly used as surge suppression components. From the original intention of designing the power-on surge suppression circuit, the fixed resistor can meet the basic function of the design - to suppress the power-on charging current.

However, the fixed resistor itself brings new safety hazards - due to the possibility that the relay connected in parallel with the "surge suppression component" cannot be effectively closed, such as mechanical fatigue, drive failure, load failure, etc., the continuous load current flow Passing this high-resistance fixed resistor (commonly used resistance is 10~100 ohms) will inevitably produce extremely high temperatures, causing the "cement resistor" to smoke, explode and other unsafe phenomena. In extreme cases, the PCB will be melted by the high temperature. Destroy or even ignite. This is a shortcoming of linear resistors in surge suppression applications. To solve this problem, Huaju Electronics has launched a positive temperature coefficient ceramic thermistor PTC with surge suppression function.Its unique positive temperature coefficient characteristic (that is, the resistance increases as the temperature increases) can effectively suppress the continuous increase in the temperature of the device itself. The temperature change process is as follows:

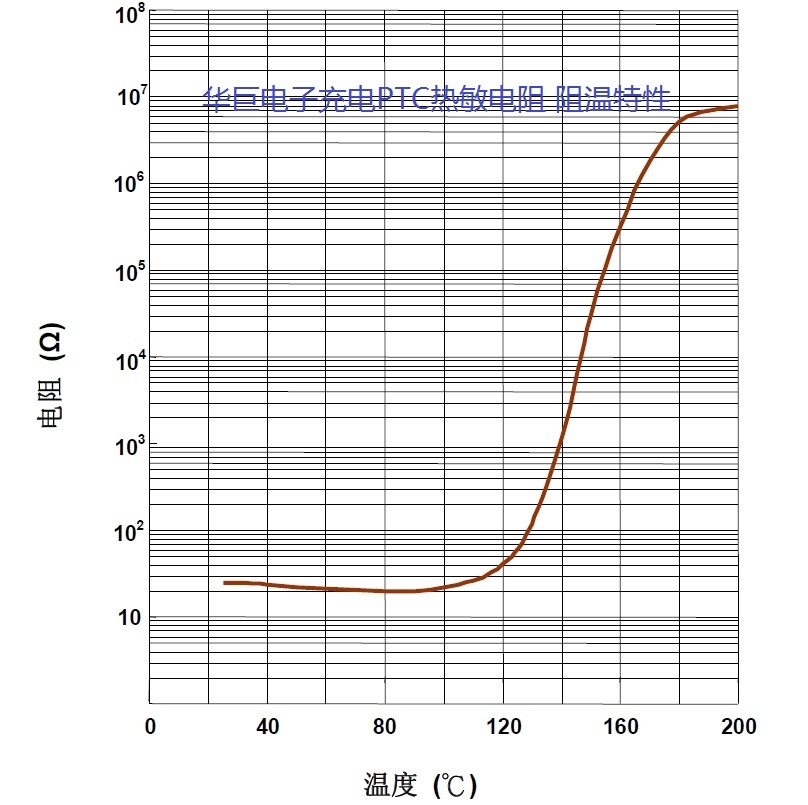

PTC has low temperature and low resistance => is heated by current => temperature increases => (when exceeding the PTC thermistor operating temperature) resistance increases => current decreases => thermal power decreases => PTC resistance continues to increase ( Until tens of KΩ) => heat generation and heat dissipation are balanced => PTC temperature is maintained near the operating point (about 130~150°C).

Small and medium-power general-purpose inverters are generally voltage-type inverters that adopt an AC-DC-AC working mode. When the inverter is first powered on, because the filter capacitor on the DC side has a very large capacity, the current is equivalent to a short circuit at the moment of charging, and the current will be very large. If there is no charging resistor between the rectifier bridge and the electrolytic capacitor, it is equivalent to a direct short circuit of the 380V power supply to the ground. In an instant, the rectifier bridge will pass infinite current and cause the rectifier bridge to explode. After adding the current limit of the charging resistor, the charging resistor consumes a lot of power if there are no relays or other components. For example, for a 22kW inverter, there is at least 45A current on the PN terminal (DC bus). If there is a problem with the "connection to the control circuit" part (such as a quality problem with the relay or thyristor), the charging resistor will be broken due to excessive heat after the inverter is running for a while. Therefore, the charging resistor is connected in series in the charging circuit to limit current charging at the moment of power-on to protect some input circuit components such as the rectifier. It is also called a buffer resistor or starting resistor in some books.

Therefore, Huaju's surge suppression PTC thermistor provides help to improve the safety and reliability of switching power supplies. It is an ideal startup surge current suppression component. This product is gradually being widely used in air conditioners, industrial inverters, Provide safe and reliable power-on surge protection for power supply and other industries.

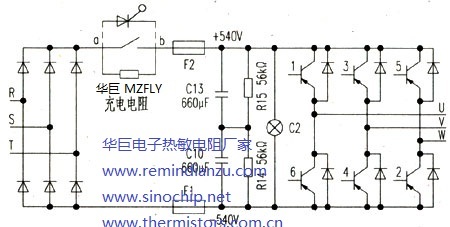

1.Charging resistor

Small and medium-power general-purpose inverters are generally voltage-type inverters that adopt an AC-DC-AC working mode. When the inverter is first powered on, because the filter capacitor on the DC side has a very large capacity, the current is equivalent to a short circuit at the moment of charging, and the current will be very large. If there is no charging resistor between the rectifier bridge and the electrolytic capacitor, it is equivalent to a direct short circuit of the 380V power supply to the ground. In an instant, the rectifier bridge will pass infinite current and cause the rectifier bridge to explode. After adding the current limit of the charging resistor, the charging resistor consumes a lot of power if there are no relays or other components. For example, for a 22kW inverter, there is at least 45A current on the PN terminal (DC bus). If there is a problem with the "connection to the control circuit" part (such as a quality problem with the relay or thyristor), the charging resistor will be broken due to excessive heat after the inverter is running for a while. Therefore, the charging resistor is connected in series in the charging circuit to limit current charging at the moment of power-on to protect some input circuit components such as the rectifier. It is also called a buffer resistor or starting resistor in some books. Siemens 6SE701G variable frequency starting circuit is shown in the attached figure.

After charging is completed, the control circuit short-circuits the resistor through the contacts of the relay or the thyristor to complete the power-on process of the inverter. If the AC input power of the frequency converter is frequently switched on and off, or the contacts of the bypass contactor are in poor contact or the conduction resistance of the thyristor becomes large, repeated charging or charging for too long will cause the charging resistor to burn out. Therefore, before replacing the charging resistor, the cause must be found out before the inverter can be put into use.

However, during the startup of some inverters, the CPU has a voltage detection and frequency reduction action. If the contactor coil lead terminal is loose and causes poor contact, the contactor fails to close, and the larger current during startup will form a larger current on the charging resistor. A large voltage drop or a sharp drop in the main circuit DC voltage is detected by the voltage detection circuit, and the CPU will issue a frequency reduction command. When there is no load or light load, the detection circuit will "timely report" the undervoltage fault, and the CPU will shut down immediately. Protect. The resistor has no time to burn out, and the inverter has shut down for protection.

So, how to choose the resistance value of the charging resistor?

After the 380V AC is rectified, the electrolytic capacitor is charged through the charging resistor. When the charge reaches a certain value (such as DC200V), the auxiliary power supply starts to supply power to the control board, allowing the control board to work so that the relay or thyristor is turned on, and the charging resistor no longer works. At the moment of power-on, the smaller the charging resistance, the greater the current flowing through the rectifier bridge. Beginner inverter repairmen often call for consultation. After replacing the charging resistor, the rectifier bridge is blown up as soon as the inverter is turned on. Is it because the charging resistor is too small? The answer is no.

In fact, when the power is turned on, the rectifier bridge is usually blown up when the power is turned on, not because the selected charging resistor R is too small, but because R is too large and the rectifier bridge is blown up. Because after the inverter is turned on, the current is charged through the charging resistor. When the charged power is enough to start the auxiliary power supply (such as 200V), the CPU works and sends a signal to the relay or thyristor to turn on. At the moment when the relay is turned on, the voltage at point b of the relay is very low (larger than 200V), while the voltage at point a is AC380V which is directly rectified and is about DC540V, so the voltage difference between terminals a and b is very large. At the moment of triggering and conduction, the current is very large, just like there is a small resistor between a and b, and a voltage of several hundred volts is applied instantly. In this way, the current flowing through the rectifier bridge is much greater than the rated current of the rectifier bridge, so the rectifier The bridge blew up.

The greater the power of the frequency converter, the smaller the charging resistance. Because the greater the power of the frequency converter, the greater the capacity of the electrolytic capacitor required, and the greater the capacity of the capacitor, the longer it takes to charge. RC determines the charging time. If you want the charging time to be as short as possible, you can only make the charging resistor R smaller. General charging resistor selection: the maximum value should not exceed 300Ω, and the minimum value should be greater than or equal to 10Ω. For high-power inverters, choose a small charging resistance, and for small-power inverters, choose a large charging resistance.

2. Energy storage capacitor

Selection of energy storage capacitor capacity: Generally, the empirical value is ≥60μF/A. For example, a 15kW inverter with a rated current of 30A requires a capacitance of ≥60μF/A×30A, which is at least 1800μF. Therefore, four 2200μF (two in parallel and two series) or two 4700μF capacitors (two in series) are generally selected. ). Of course, the brand of the selected capacitor must also be considered. Different brands have great differences in quality.

Some people repair the inverter and only replace the damaged inverter module. It often doesn't take long for the module to be damaged again. When this happens, there will be complaints about poor module quality, poor user environment, etc. In fact, the most important reason is that they did not find out the cause of the damage to the inverter module and did not completely eliminate the hidden fault.

In addition to long-term overloading, poor heat dissipation and lightning strikes, the damage to the inverter module is due to internal causes such as capacitor capacity reduction, capacitance loss and failure, which are the fatal killers of its damage! Its harmfulness cannot be ignored. The capacity decreases, which may manifest as poor load carrying capacity. When the load increases, it often causes a DC link undervoltage gate failure. When the capacitor is further damaged, it will cause a fatal blow to the inverter module. At this time, the voltage detection circuit has no time to make a decision. reaction, a fault is reported, causing damage to the inverter module.

After the capacitor is defective or failed (or the capacity becomes smaller), there will be no abnormality on the surface when running with a small power load (large horse-drawn cart), but the situation will be different after a larger power load is connected (full load operation). At this time, the DC circuit of the frequency converter has completely (or partially) lost its energy storage filtering capability. The DC loop is a pulsating DC with a frequency of 300Hz. The current drawn when the motor is started increases the pulsating component of the pulsating current. This is one of the reasons why choosing a small resistor is detrimental to the high-voltage capacitor, and choosing a large resistor is one of the reasons why it is easy to explode. In addition, if the back electromotive force of the motor winding or a certain output carrier of the frequency converter happens to fall within the range of the pulsating DC, the two superimpose each other, and the sharp change of the pulsating current in the entire system happens to fall at a certain frequency point. , the distributed inductance and distributed capacitance in the circuit are added from time to time, and the addition and interaction of various unfavorable factors cause the dynamic energy in the circuit to rise sharply, and an instant dangerous resonant overvoltage appears at this time! In the inverter module The IGBT tubes and the peak voltage absorbing diodes in the circuit have a certain or even large withstand voltage under normal conditions, but under the high voltage impact that is several times higher than the withstand voltage value, there is no The ability to parry also appears to be very fragile. It is not surprising that overvoltage explosions and breakdown short circuits occur. Although the frequency converter has a complete voltage or current protection detection circuit, if it often faces such instantaneous voltage distortion, it will appear incompetent, or sometimes it will not be able to respond in a timely manner.

However, faults in energy storage capacitors are often hidden and can be said to be soft faults that are easily overlooked. Some capacitors seem to have no problem when measuring their capacity and can operate, but they are a major hidden danger during operation. Especially for the capacitors in high-power frequency converters, if the environment is harsh and the capacitors are operated for a long time, the lead electrodes will be subjected to large current charging and discharging impacts of hundreds of hertz over the years, resulting in varying degrees of corrosion and oxidation. When measured with a capacitance meter, the capacity will be found to be zero. If it is abnormal, but it is connected in the circuit, the internal resistance of charging and discharging will increase, causing the DC circuit voltage to drop, and the inverter will not work normally, causing the maintenance personnel to make misjudgments and take detours. Let me emphasize again: after the energy storage capacitor loses its capacity, it is very easy for the module to burst due to resonant overvoltage.

The advantages of PTC thermistor charging resistor over traditional charging resistor are:

Built-in self-protection function

Under normal operating conditions, the PTC ICL acts as an ordinary resistor. When the power is turned on and the component temperature is the same as the ambient temperature, the resistance of the PTC ICL varies between 20 ohms and 500 ohms depending on the model. This is enough to limit the peak inrush current. Once the DC link capacitors are fully charged, the PTC ICL is bypassed,

If the charging circuit fails, the special function of the PTC thermistor comes into play to protect the circuit. When current passes through this component, the temperature of the PTC thermistor will increase and the resistance will also increase significantly. Therefore, thanks to its self-protection function, PTC thermistor has inherent advantages in the following failure modes:

– Capacitor short circuit

– The current limiting element is not bypassed (switching element fails) when the DC link capacitors are charged.

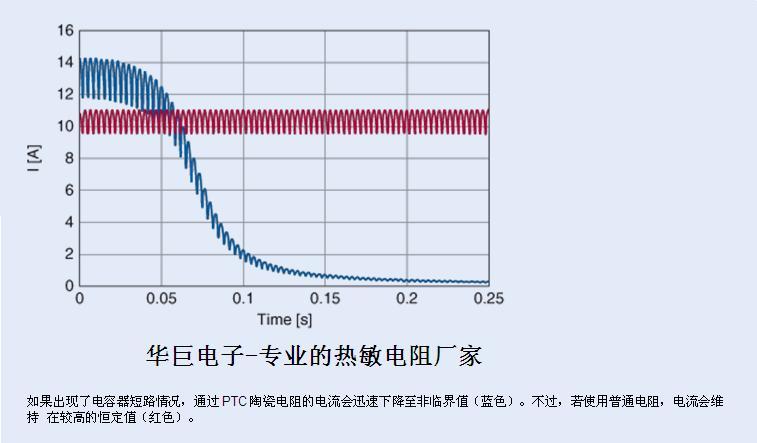

All these failure modes have one thing in common: thermal stress on the current limiting element. There are two ways to ensure that the ICL component will not be damaged in similar situations: use a power resistor with a sufficient power rating or use a PTC thermistor. The design of SINOCHIP PTC ICL allows it to work when directly connected to the supply voltage of the maximum rated voltage without the need for additional current limiting measures because the PTC ICL has a self-protection function. In the event of excessive current flow, such as a short circuit, the PTC temperature will increase, causing its resistance to rise significantly, allowing the PTC thermistor itself to limit the current to non-critical levels (Figure 4).

Figure 4: Current curve when capacitor is short-circuited

If a capacitor short circuit occurs, the current through the PTC ceramic resistor will quickly drop to a non-critical value (blue). However, if a normal resistor is used, the current will remain at a higher constant value (red).

SINOCHIP PTC thermistors have some key advantages as active surge current limiting ICL components in some applications:

– Its ICL functionality is not affected by extreme operating temperatures.

– Effective inrush current limitation is achieved as soon as the load is switched off and cooling is already taking place during normal operation.

– Has self-protection function against current overload caused by circuit fault.

Charging control circuit for energy storage capacitor

Self-protecting charging resistors based on PTC (positive temperature coefficient) ceramics are used to smooth capacitors in power supplies. When a short circuit occurs, they limit the current flow to a safe level.

Ordinary resistors are often used to limit current when charging capacitors. However, this often involves technical risks. For example, when a capacitor is shorted, the resistor will be continuously exposed to high power levels if the capacitor shorts or if the relay fails. This can lead to damage to the resistor or the entire system. Huaju Electronics adopts the new BPFLY series charging resistors based on PTC ceramics and has now developed a professional solution:

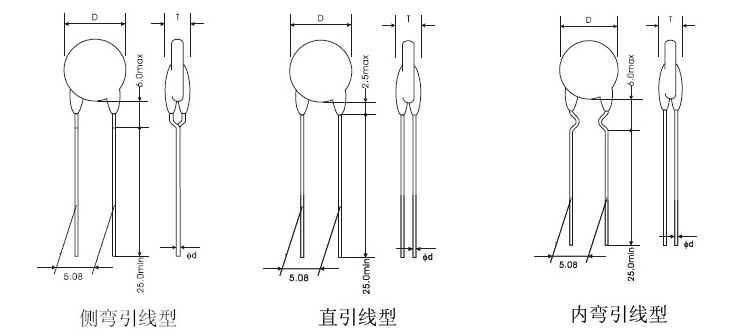

1. Main technical parameters

model

Zero power resistor R25

maximum voltage

Heat capacity

Maximum immobile energy

Operating temperature

(Ω)

Vmax

Cth(J/K)

ENon(J)

(℃)

(Vac) Vdc 25℃ 40℃ 60℃ Power frequency voltage 260Vac

BPFLY-07D120T70RH-260

70

260

370

0.15

14 12 9 -55~+85

BPFLY-07D120T80RH-260

80

260

370

0.15

14 12 9 BPFLY-07D120T101RH-260

100

260

370

0.15

14 12 9 BPFLY-07D120T121RH-260

120

260

370

0.15

14 12 9 BPFLY-07D120T151RH-260

150

260

370

0.15

14 12 9 BPFLY-07D120T201RH-260

200

260

370

0.15

14 12 9 BPFLY-07D120T251RH-260

250

260

370

0.15

14 12 9 BPFLY-07D120T401RH-260

400

260

370

0.15

14 12 9 BPFLY-07D120T501RH-260

500

260

370

0.15

14 12 9 BPFLY-07D120T102RH-260

1000

260

370

0.3

28 twenty four 18 BPFLY-08D120T70RH-260

70

260

370

0.3

28 twenty four 18 BPFLY-08D120T80RH-260

80

260

370

0.3

28 twenty four 18 BPFLY-08D120T101RH-260

100

260

370

0.3

28 twenty four 18 BPFLY-08D120T121RH-260

120

260

370

0.3

28 twenty four 18 BPFLY-08D120T151RH-260

150

260

370

0.3

28 twenty four 18 BPFLY-08D120T201RH-260

200

260

370

0.3

28 twenty four 18 BPFLY-08D120T251RH-260

250

260

370

0.3

28 twenty four 18 BPFLY-08D120T401RH-260

400

260

370

0.3

28 twenty four 18 BPFLY-08D120T501RH-260

500

260

370

0.3

28 twenty four 18 BPFLY-08D120T102RH-260

1000

260

370

0.3

28 twenty four 18 BPFLY-09D120T70RH-260

70

260

370

0.4

38 32 twenty four

BPFLY-09D120T101RH-260

100

260

370

0.4

38 32 twenty four

BPFLY-09D120T121RH-260

120

260

370

0.4

38 32 twenty four

BPFLY-09D120T151RH-260

150

260

370

0.4

38 32 twenty four

BPFLY-09D120T201RH-260

200

260

370

0.4

38 32 twenty four

BPFLY-09D251T251RH-260

250

260

370

0.4

38 32 twenty four

BPFLY-09D501T501RH-260

500

260

370

0.4

38 32 twenty four

BPFLY-09D120T102RH-260

1000

260

370

0.4

38 32 twenty four

BPFLY-11D120T10RH-260

10

260

370

0.6

57 48 36

BPFLY-11D120T15RH-260

15

260

370

0.6

57 48 36

BPFLY-11D120T20RH-260

20

260

370

0.6

57 48 36

BPFLY-11D120T30RH-260

30

260

370

0.6

57 48 36

BPFLY-11D120T50RH-260

50

260

370

0.6

57 48 36

BPFLY-11D120T70RH-260

70

260

370

0.6

57 48 36

BPFLY-11D120T101RH-260

100

260

370

0.6

57 48 36

BPFLY-11D120T151RH-260

150

260

370

0.6

57 48 36

BPFLY-11D120T201RH-260

200

260

370

0.6

57 48 36

BPFLY-11D120T251RH-260

250

260

370

0.6

57 48 36

BPFLY-11D120T401RH-260

400

260

370

0.6

57 48 36

BPFLY-11D120T501RH-260

500

260

370

0.6

57 48 36

BPFLY-11D120T801RH-260

800

260

370

0.6

57 48 36

BPFLY-11D120T102RH-260

1000

260

370

0.6

57 48 36

BPFLY-14D120T6R0H-260

6

260

370

1.0

95 80 60

BPFLY-14D120T10RH-260

10

260

370

1.0

95 80 60

BPFLY-14D120T15RH-260

15

260

370

1.0

95 80 60

BPFLY-14D120T18RH-260

18

260

370

1.0

95 80 60

BPFLY-14D120T25RH-260

25

260

370

1.0

95 80 60

BPFLY-14D120T30RH-260

30

260

370

1.0

95 80 60

BPFLY-14D120T45RH-260

45

260

370

1.0

95 80 60

BPFLY-14D120T50RH-260

50

260

370

1.0

95 80 60

BPFLY-14D120T70RH-260

70

260

370

1.0

95 80 60

BPFLY-14D120T101RH-260

100

260

370

1.0

95 80 60

BPFLY-14D120T151RH-260

150

260

370

1.0

95 80 60

BPFLY-14D120T201RH-260

200

260

370

1.0

95 80 60

BPFLY-14D120T251RH-260

250

260

370

1.0

95 80 60

BPFLY-14D120T401RH-260

400

260

370

1.0

95 80 60

BPFLY-14D120T501RH-260

500

260

370

1.0

95 80 60

BPFLY-14D120T801RH-260

800

260

370

1.0

95 80 60

BPFLY-14D120T102RH-260

1000

260

370

1.0

95 80 60

BPFLY-18D120T6R0H-260

6

260

370

1.5

143 120 90

BPFLY-18D120T10RH-260

10

260

370

1.5

143 120 90

BPFLY-18D120T15RH-260

15

260

370

1.5

143 120 90

BPFLY-18D120T18RH-260

18

260

370

1.5

143 120 90

BPFLY-18D120T25RH-260

25

260

370

1.5

143 120 90

BPFLY-18D120T30RH-260

30

260

370

1.5

143 120 90

BPFLY-18D120T45RH-260

45

260

370

1.5

143 120 90

BPFLY-18D120T50RH-260

50

260

370

1.5

143 120 90

BPFLY-18D120T70RH-260

70

260

370

1.5

143 120 90

BPFLY-18D120T101RH-260

100

260

370

1.5

143 120 90

BPFLY-18D120T151RH-260

150

260

370

1.5

143 120 90

BPFLY-18D120T201RH-260

200

260

370

1.5

143 120 90

BPFLY-18D120T251RH-260

250

260

370

1.5

143 120 90

BPFLY-18D120T401RH-260

400

260

370

1.5

143 120 90

BPFLY-18D120T501RH-260

500

260

370

1.5

143 120 90

BPFLY-18D120T801RH-260

800

260

370

1.5

143 120 90

BPFLY-18D120T102RH-260

1000

260

370

1.5

143 120 90

BPFLY-20D120T6R0H-260

6

260

370

1.9 180 152 114 BPFLY-20D120T10RH-260

10

260

370

1.9 180 152 114 BPFLY-20D120T15RH-260

15

260

370

1.9 180 152 114 BPFLY-20D120T18RH-260

18

260

370

1.9 180 152 114 BPFLY-20D120T25RH-260

25

260

370

1.9 180 152 114 BPFLY-20D120T30RH-260

30

260

370

1.9 180 152 114 BPFLY-20D120T45RH-260

45

260

370

1.9 180 152 114 BPFLY-20D120T50RH-260

50

260

370

1.9 180 152 114 BPFLY-20D120T70RH-260

70

260

370

1.9 180 152 114 BPFLY-20D120T101RH-260

100

260

370

1.9 180 152 114 BPFLY-20D120T151RH-260

150

260

370

1.9 180 152 114 BPFLY-20D120T201RH-260

200

260

370

1.9 180 152 114 BPFLY-20D120T251RH-260

250

260

370

1.9 180 152 114 BPFLY-20D120T401RH-260

400

260

370

1.9 180 152 114 BPFLY-20D120T501RH-260

500

260

370

1.9 180 152 114 BPFLY-20D120T801RH-260

800

260

370

1.9 180 152 114 BPFLY-20D120T102RH-260

1000

260

370

1.9 180 152 114 BPFLY-22D120T3R3H-260

3.3

260

370

2.4

228 192 144

BPFLY-22D120T4R7H-260

4.7

260

370

2.4

228 192 144

BPFLY-22D120T6R0H-260

6

260

370

2.4

228 192 144

BPFLY-22D120T10RH-260

10

260

370

2.4

228 192 144

BPFLY-22D120T15RH-260

15

260

370

2.4

228 192 144

BPFLY-22D120T18RH-260

18

260

370

2.4

228 192 144

BPFLY-22D120T25RH-260

25

260

370

2.4

228 192 144

BPFLY-22D120T30RH-260

30

260

370

2.4

228 192 144

BPFLY-22D120T45RH-260

45

260

370

2.4

228 192 144

BPFLY-22D120T50RH-260

50

260

370

2.4

228 192 144

BPFLY-22D120T70RH-260

70

260

370

2.4

228 192 144

BPFLY-22D120T101RH-260

100

260

370

2.4

228 192 144

BPFLY-22D120T151RH-260

150

260

370

2.4

228 192 144

BPFLY-22D120T201RH-260

200

260

370

2.4

228 192 144

BPFLY-22D120T251RH-260

250

260

370

2.4

228 192 144

BPFLY-22D120T401RH-260

400

260

370

2.4

228 192 144

BPFLY-22D120T501RH-260

500

260

370

2.4

228 192 144

BPFLY-22D120T801RH-260

800

260

370

2.4

228 192 144

BPFLY-22D120T102RH-260

1000

260

370

2.4

228 192 144

BPFLY-27D120T3R3H-260

3.3

260

370

3.75

356 300 225

BPFLY-27D120T4R7H-260

4.7

260

370

3.75

356 300 225

BPFLY-27D120T6R0H-260

6

260

370

3.75

356 300 225

BPFLY-27D120T10RH-260

10

260

370

3.75

356 300 225

BPFLY-27D120T15RH-260

15

260

370

3.75

356 300 225

BPFLY-27D120T18RH-260

18

260

370

3.75

356 300 225

BPFLY-27D120T25RH-260

25

260

370

3.75

356 300 225

BPFLY-27D120T30RH-260

30

260

370

3.75

356 300 225

BPFLY-27D120T45RH-260

45

260

370

3.75

356 300 225

BPFLY-27D120T50RH-260

50

260

370

3.75

356 300 225

BPFLY-27D120T70RH-260

70

260

370

3.75

356 300 225

BPFLY-27D120T101RH-260

100

260

370

3.75

356 300 225

BPFLY-27D120T151RH-260

150

260

370

3.75

356 300 225

BPFLY-27D120T201RH-260

200

260

370

3.75

356 300 225

BPFLY-27D120T251RH-260

250

260

370

3.75

356 300 225

BPFLY-27D120T401RH-260

400

260

370

3.75

356 300 225

BPFLY-27D120T501RH-260

500

260

370

3.75

356 300 225

BPFLY-27D120T801RH-260

800

260

370

3.75

356 300 225

BPFLY-27D120T102RH-260

1000

260

370

3.75

356 300 225

Power frequency voltage 280Vac

BPFLY-14D115T25RH-280

25 280 400 1.1 100 82 60 BPFLY-14D115T50RH-280

50 280 400 1.1 100 82 60 BPFLY-14D115T80RH-280

80 280 400 1.1 100 82 60 BPFLY-18D130T22RH-280

twenty two 280 400 1.6 168 152 112 BPFLY-18D130T33RH-280

33 280 400 1.6 168 152 112 BPFLY-20D130T33RH-280

twenty two 280 400 2.1 220 200 147 BPFLY-20D130T33RH-280

33 280 400 2.1 220 200 147 Power frequency voltage 440Vac

BPFLY-09D120T70RH-440

70

440

620

0.5

47.5 40 30

BPFLY-09D120T101RH-440

100

440

620

0.5

47.5 40 30

BPFLY-09D120T121RH-440

120

440

620

0.5

47.5 40 30

BPFLY-09D120T151RH-440

150

440

620

0.5

47.5 40 30

BPFLY-09D120T201RH-440

200

440

620

0.5

47.5 40 30

BPFLY-09D251T251RH-440

250

440

620

0.5

47.5 40 30

BPFLY-09D501T501RH-440

500

440

620

0.5

47.5 40 30

BPFLY-09D120T102RH-440

1000

440

620

0.5

47.5 40 30

BPFLY-11D120T50RH-440

50

440

620

0.8

76 64 48

BPFLY-11D120T70RH-440

70

440

620

0.8

76 64 48

BPFLY-11D120T101RH-440

100

440

620

0.8

76 64 48

BPFLY-11D120T151RH-440

150

440

620

0.8

76 64 48

BPFLY-11D120T201RH-440

200

440

620

0.8

76 64 48

BPFLY-11D120T251RH-440

250

440

620

0.8

76 64 48

BPFLY-11D120T401RH-440

400

440

620

0.8

76 64 48

BPFLY-11D120T501RH-440

500

440

620

0.8

76 64 48

BPFLY-11D120T801RH-440

800

440

620

0.8

76 64 48

BPFLY-11D120T102RH-440

1000

440

620

0.8

76 64 48

BPFLY-14D115T121RH-440

120 440 620 1.4 126 105 77 BPFLY-14D115T151RH-440

150 440 620 1.4 126 105 77 BPFLY-14D120T50RH-440

50

440

620

1.4

133 112 84

BPFLY-14D120T70RH-440

70

440

620

1.4

133 112 84

BPFLY-14D120T101RH-440

100

440

620

1.4

133 112 84

BPFLY-14D120T151RH-440

150

440

620

1.4

133 112 84

BPFLY-14D120T201RH-440

200

440

620

1.4

133 112 84

BPFLY-14D120T251RH-440

250

440

620

1.4

133 112 84

BPFLY-14D120T401RH-440

400

440

620

1.4

133 112 84

BPFLY-14D120T501RH-440

500

440

620

1.4

133 112 84

BPFLY-14D120T801RH-440

800

440

620

1.4

133 112 84

BPFLY-14D120T102RH-440

1000

440

620

1.4

133 112 84

BPFLY-18D120T50RH-440

50

440

620

2.1

200 168 126

BPFLY-18D120T70RH-440

70

440

620

2.1

200 168 126

BPFLY-18D120T101RH-440

100

440

620

2.1

200 168 126

BPFLY-18D120T151RH-440

150

440

620

2.1

200 168 126

BPFLY-18D120T201RH-440

200

440

620

2.1

200 168 126

BPFLY-18D120T251RH-440

250

440

620

2.1

200 168 126

BPFLY-18D120T401RH-440

400

440

620

2.1

200 168 126

BPFLY-18D120T501RH-440

500

440

620

2.1

200 168 126

BPFLY-18D120T801RH-440

800

440

620

2.1

200 168 126

BPFLY-18D120T102RH-440

1000

440

620

2.1

200 168 126

BPFLY-18D130T56RH-440

56 440 620 2.1 220 190 147 BPFLY-18D135T30RH-440

30 440 620 2.1 230 200 157 BPFLY-20D120T30RH-440

30

440

620

2.6 247 208 156 BPFLY-20D120T45RH-440

45

440

620

2.6 247 208 156 BPFLY-20D120T50RH-440

50

440

620

2.6 247 208 156 BPFLY-20D120T70RH-440

70

440

620

2.6 247 208 156 BPFLY-20D120T101RH-440

100

440

620

2.6 247 208 156 BPFLY-20D120T151RH-440

150

440

620

2.6 247 208 156 BPFLY-20D120T201RH-440

200

440

620

2.6 247 208 156 BPFLY-20D120T251RH-440

250

440

620

2.6 247 208 156 BPFLY-20D120T401RH-440

400

440

620

2.6 247 208 156 BPFLY-20D120T501RH-440

500

440

620

2.6 247 208 156 BPFLY-20D120T801RH-440

800

440

620

2.6 247 208 156 BPFLY-20D120T102RH-440

1000

440

620

2.6 247 208 156 BPFLY-20D130T56RH-440

56 440 620 2.6 273 234 182 BPFLY-20D135T30RH-440

30 440 620 2.6 286 247 195 BPFLY-22D120T50RH-440

50

440

620

3.5

322 280 210

BPFLY-22D120T70RH-440

70

440

620

3.5

322 280 210

BPFLY-22D120T101RH-440

100

440

620

3.5

322 280 210

BPFLY-22D120T151RH-440

150

440

620

3.5

322 280 210

BPFLY-22D120T201RH-440

200

440

620

3.5

322 280 210

BPFLY-22D120T251RH-440

250

440

620

3.5

322 280 210

BPFLY-22D120T401RH-440

400

440

620

3.5

322 280 210

BPFLY-22D120T501RH-440

500

440

620

3.5

322 280 210

BPFLY-22D120T801RH-440

800

440

620

3.5

322 280 210

BPFLY-22D120T102RH-440

1000

440

620

3.5

322 280 210

BPFLY-27D120T50RH-440

50

440

620

5.4

513 432 324

BPFLY-27D120T70RH-440

70

440

620

5.4

513 432 324

BPFLY-27D120T101RH-440

100

440

620

5.4

513 432 324

BPFLY-27D120T151RH-440

150

440

620

5.4

513 432 324

BPFLY-27D120T201RH-440

200

440

620

5.4

513 432 324

BPFLY-27D120T251RH-440

250

440

620

5.4

513 432 324

BPFLY-27D120T401RH-440

400

440

620

5.4

513 432 324

BPFLY-27D120T501RH-440

500

440

620

5.4

513 432 324

BPFLY-27D120T801RH-440

800

440

620

5.4

513 432 324

BPFLY-27D120T102RH-440

1000

440

620

5.4

513 432 324

Power frequency voltage 480Vac

BPFLY-18D130T121RH-480

120 480 680 2.1 220 189 147 Power frequency voltage 560Vac

BPFLY-14D110T501RH-560

500 560 800 1.4 120 98 70 BPFLY-18D130T101RH-560

100 560 800 2.3 247 207 161 Power frequency voltage 680Vac

BPFLY-14D120T50RH-680 50

680

1000

2.2 210 176 132 BPFLY-14D120T70RH-680 70

680

1000

2.2 210 176 132 BPFLY-14D120T101RH-680 100

680

1000

2.2 210 176 132 BPFLY-14D120T121RH-680 120

680

1000

2.2 210 176 132 BPFLY-14D120T151RH-680 150

680

1000

2.2 210 176 132 BPFLY-14D120T201RH-680 200

680

1000

2.2 210 176 132 BPFLY-14D120T251RH-680 250

680

1000

2.2 210 176 132 BPFLY-14D120T351RH-680 350

680

1000

2.2 210 176 132 BPFLY-14D120T501RH-680 500

680

1000

2.2 210 176 132 BPFLY-14D120T801RH-680 800

680

1000

2.2 210 176 132 BPFLY-14D120T102RH-680 1000

680

1000

2.2 210 176 132 BPFLY-18D120T50RH-680

50

680

1000

3.5 322 280 210 BPFLY-18D120T70RH-680

70

680

1000

3.5 322 280 210 BPFLY-18D120T101RH-680

100

680

1000

3.5 322 280 210 BPFLY-18D120T151RH-680

150

680

1000

3.5 322 280 210 BPFLY-18D120T201RH-680

200

680

1000

3.5 322 280 210 BPFLY-18D120T251RH-680

250

680

1000

3.5 322 280 210 BPFLY-18D120T401RH-680

400

680

1000

3.5 322 280 210 BPFLY-18D120T501RH-680

500

680

1000

3.5 322 280 210 BPFLY-18D120T801RH-680

800

680

1000

3.5 322 280 210 BPFLY-18D120T102RH-680

1000

680

1000

3.5 322 280 210 BPFLY-20D120T50RH-680

50

680

1000

4.5 428 360 270 BPFLY-20D120T70RH-680

70

680

1000

4.5 428 360 270 BPFLY-20D120T101RH-680

100

680

1000

4.5 428 360 270 BPFLY-20D120T151RH-680

150

680

1000

4.5 428 360 270 BPFLY-20D120T201RH-680

200

680

1000

4.5 428 360 270 BPFLY-20D120T251RH-680

250

680

1000

4.5 428 360 270 BPFLY-20D120T401RH-680

400

680

1000

4.5 428 360 270 BPFLY-20D120T501RH-680

500

680

1000

4.5 428 360 270 BPFLY-20D120T801RH-680

800

680

1000

4.5 428 360 270 BPFLY-20D120T102RH-680

1000

680

1000

4.5 428 360 270 BPFLY-22D120T50RH-680

50

680

1000

5.45 517 436 320 BPFLY-22D120T70RH-680

70

680

1000

5.45 517 436 320 BPFLY-22D120T101RH-680

100

680

1000

5.45 517 436 320 BPFLY-22D120T151RH-680

150

680

1000

5.45 517 436 320 BPFLY-22D120T201RH-680

200

680

1000

5.45 517 436 320 BPFLY-22D120T251RH-680

250

680

1000

5.45 517 436 320 BPFLY-22D120T401RH-680

400

680

1000

5.45 517 436 320 BPFLY-22D120T501RH-680

500

680

1000

5.45 517 436 320 BPFLY-22D120T801RH-680

800

680

1000

5.45 517 436 320 BPFLY-22D120T102RH-680

1000

680

1000

5.45 517 436 320 BPFLY-27D120T50RH-680

50

680

1000

8.50 810 680 510 BPFLY-27D120T70RH-680

70

680

1000

8.50 810 680 510 BPFLY-27D120T101RH-680

100

680

1000

8.50 810 680 510 BPFLY-27D120T151RH-680

150

680

1000

8.50 810 680 510 BPFLY-27D120T201RH-680

200

680

1000

8.50 810 680 510 BPFLY-27D120T251RH-680

250

680

1000

8.50 810 680 510 BPFLY-27D120T401RH-680

400

680

1000

8.50 810 680 510 BPFLY-27D120T501RH-680

500

680

1000

8.50 810 680 510 BPFLY-27D120T801RH-680

800

680

1000

8.50 810 680 510 BPFLY-27D120T102RH-680

1000

680

1000

8.50 810 680 510

Application and selection

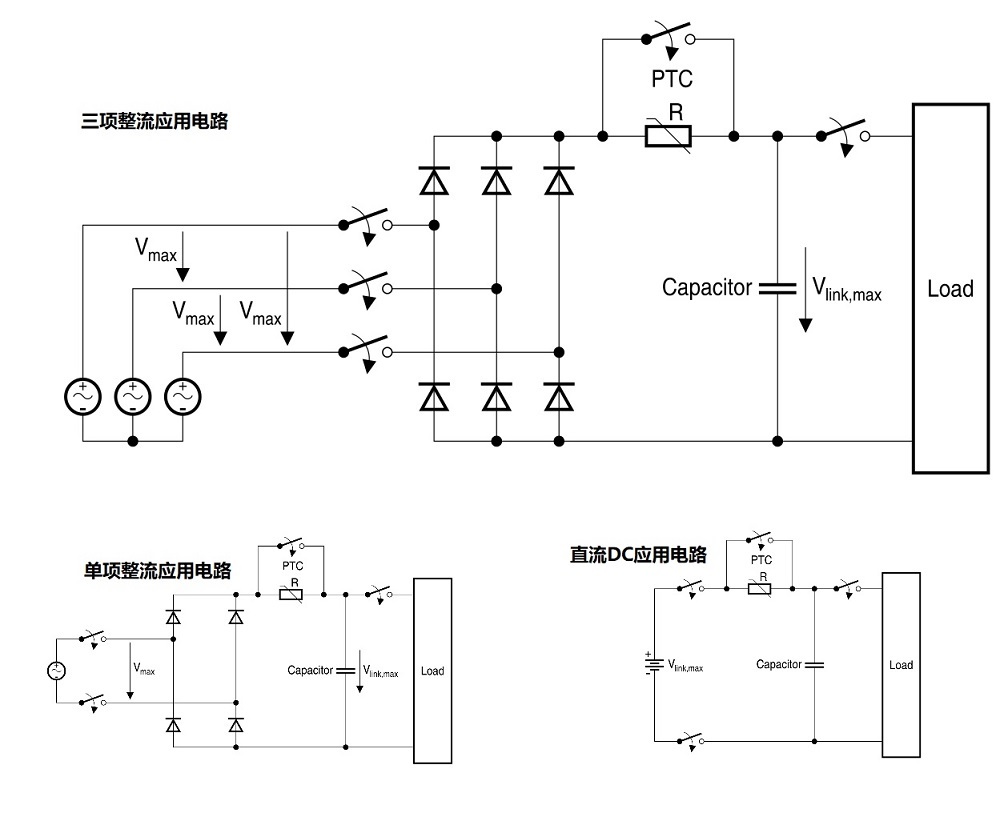

l Typical application circuit:

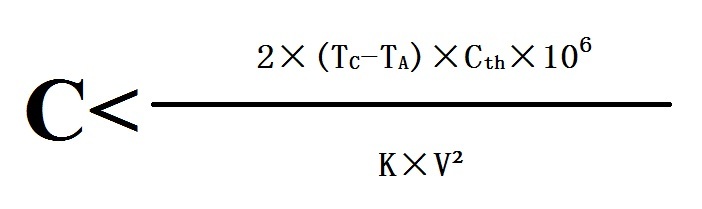

ⅡSelection

Select the charging capacitor according to the following formula

C: Filter capacitor.

Tc: Curie temperature of PTC Ta: ambient temperature

V: The highest charging voltage across the capacitor, the power supply voltage is AC, and V is the peak value of AC.

K coefficient K = 1 for DC, K = 0.96 for three-phase AC rectifier, K = 0.76 for half-wave rectifier

When a single PTC surge suppression thermistor cannot meet the requirements, multiple PTC surge suppression thermistors can be used in parallel.

The maximum load capacitance of the PTC soft-start resistor is inversely proportional to the square of the voltage across the capacitor when the capacitor is fully charged. Therefore, under the same environmental conditions, the maximum load capacitance can be increased by 4 times with half the voltage drop.

PTC charged capacity calculation tool

EPCOS material number Huaju replacement comparison table

EPCOS (EPCOS) Sinochip (Huaju) alternative material number B59213J0130A020 MZFLY-18D130T33RH-280 B59215J0130A020 MZFLY-18D130T22RH-280 B59217J0130A020 MZFLY-18D130T56RH-440 B59219J0130A020 MZFLY-18D130T101RH-560 B59105J0130A020 MZFLY-18D130T22RH-280 B59107J0130A020 MZFLY-18D130T56RH-440 B59109J0130A020 MZFLY-18D130T101RH-560 B59201J0140B010 MZFLY-18D135T20RH-380 B59202J0135B010 MZFLY-18D135T30RH-440 B59204J0130B010 MZFLY-18D130T101RH-560 B59750B0120A070 MZFLY-14D115T25RH-280 B59751B0120A070 MZFLY-14D115T50RH-280 B59752B0120A070 MZFLY-14D115T80RH-280 B59753B0120A070 MZFLY-14D115T121RH-440 B59754B0120A070 MZFLY-14D115T151RH-440 B59755B0120A070 MZFLY-14D110T501RH-560 B59770B0120A070 MZFLY-09D120T70RH-260 B59771B0120A070 MZFLY-09D120T121RH-260 B59772B0120A070 MZFLY-09D120T151RH-260 B59773B0120A070 MZFLY-09D120T501RH-440 B59412C1130A070 MZFLY-18D130T121RH-480 B59451C1130A070 MZFLY-18D130T56RH-440 B59750C0120A070 MZFLY-14D115T25RH-280 B59751C0120A070 MZFLY-14D115T50RH-280 B59755C0115A070 MZFLY-14D115T501RH-560

Key words:

Inverter energy storage capacitor surge suppression self-restoring PTC thermistor

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!