PPTC overcurrent protection sheet for circular batteries

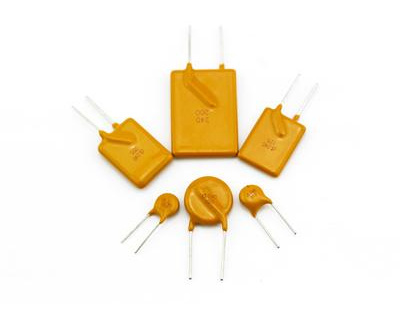

The resettable fuse is a heat-sensitive semiconductor material. The sensitivity itself is not high. If the sensitivity is not considered, it can be used. The main parameter of the fuse is the fusing current. As long as the withstand voltage exceeds the voltage in the actual circuit, it will be fine. For example, we often Glass tube fuses generally have a withstand voltage of 250VAC, but in actual application, it is the same whether it is AC or DC, whether it is 220V or 12V. What you need to consider is whether the fusing current is highly sensitive or needs to be broken quickly. The fuse is that the self-restoring fuse is a slow-blow type fuse. The material of the self-restoring fuse generates heat after being energized. When the current is too large and the heat reaches a certain level, the material will no longer conduct electricity. This is the same as ordinary fuses, except that Ordinary fuses only blow once. Resettable fuses are composed of specially treated polymer resin (Polymer) and conductive particles (Carbon Black) distributed inside. Under normal operation, the polymer resin tightly binds the conductive particles outside the crystal structure, forming a chain-like conductive path. At this time, the resettable fuse is in a low resistance state (a), and the current flowing through the resettable fuse on the line generates The heat energy is small and will not change the crystal structure. When a line is short-circuited or overloaded, the heat generated by the large current flowing through the resettable fuse melts the polymer resin, and the volume grows rapidly, forming a high-resistance state (b), and the operating current decreases rapidly, thereby limiting and protecting the circuit. When the fault is eliminated, the resettable fuse re-cools and crystallizes, shrinks in volume, and the conductive particles re-form a conductive path. The resettable fuse returns to a low-resistance state, thus completing the protection of the circuit without manual replacement.

- Commodity name: PPTC overcurrent protection sheet for circular batteries

- 产品描述

- 产品规格及参数

-

The resettable fuse is a heat-sensitive semiconductor material. The sensitivity itself is not high. If the sensitivity is not considered, it can be used. The main parameter of the fuse is the fusing current. As long as the withstand voltage exceeds the voltage in the actual circuit, it will be fine. For example, we often Glass tube fuses generally have a withstand voltage of 250VAC, but in actual application, it is the same whether it is AC or DC, whether it is 220V or 12V. What you need to consider is whether the fusing current is highly sensitive or needs to be broken quickly. The fuse is that the self-restoring fuse is a slow-blow type fuse. The material of the self-restoring fuse generates heat after being energized. When the current is too large and the heat reaches a certain level, the material will no longer conduct electricity. This is the same as ordinary fuses, except that Ordinary fuses only blow once. Resettable fuses are composed of specially treated polymer resin (Polymer) and conductive particles (Carbon Black) distributed inside. Under normal operation, the polymer resin tightly binds the conductive particles outside the crystal structure, forming a chain-like conductive path. At this time, the resettable fuse is in a low resistance state (a), and the current flowing through the resettable fuse on the line generates The heat energy is small and will not change the crystal structure. When a line is short-circuited or overloaded, the heat generated by the large current flowing through the resettable fuse melts the polymer resin, and the volume grows rapidly, forming a high-resistance state (b), and the operating current decreases rapidly, thereby limiting and protecting the circuit. When the fault is eliminated, the resettable fuse re-cools and crystallizes, shrinks in volume, and the conductive particles re-form a conductive path. The resettable fuse returns to a low-resistance state, thus completing the protection of the circuit without manual replacement.

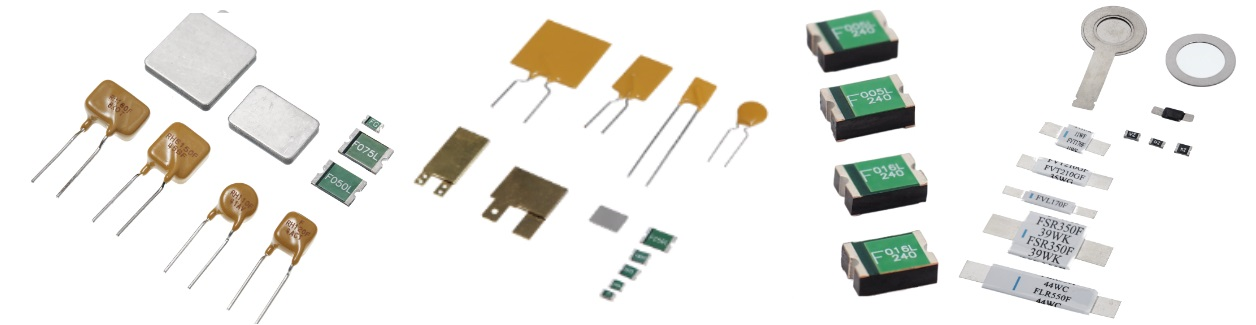

Huaju Electronics is one of the earliest domestic manufacturers engaged in the R&D and production of resettable fuses for overcurrent protection products. The company mainly engages in the R&D and production of thermistors, varistors, and resettable fuses. Relying on its strong R&D capabilities, the company has recently launched a low-power, low-resistance chip resettable fuse, which is suitable for battery-powered handheld devices and can effectively increase the use time of the device. It is another flagship product of the company. The company's plug-in resettable fuses (PPTC&CPTC), chip resettable fuses, and chip fuses (fast-blow chip fuses/slow-blow chip fuses) are widely used in military, medical, human life, industrial automation, and automobiles. , security and fire protection, home appliances, communications and other fields and occasions that require over-current protection and over-load protection. We are one of the few manufacturers in the world that masters the core technology of polymer over-current protection components and ceramic over-current protection components. Huaju Resettable Fuse Company has always been adhering to the principle of technology-based and application-led to continuously develop self-resettable fuse products that meet current needs. Our R&D team not only has the technical background of the Institute of Metals, Chinese Academy of Sciences, but also has strong technical force. Our self-resettable fuses All indicators of fuse products meet the standards of domestic and foreign authoritative organizations; we have senior engineers from the United States and Taiwan who have many years of experience in the development and application of PPTC resettable fuses and CPTC resettable fuses, and have successively developed low-power resettable fuses for handheld devices. New products such as ceramic substrate chip resettable fuses, PPTC overcurrent protection sheets and high voltage and high holding current resettable fuses are used to replace some products that we could not produce domestically and had to rely on imports. We provide a variety of resettable fuses that can meet the high standards and stringent needs of today's high-tech applications. The quality and performance of Huaju Electronics' resettable fuse products can completely replace imported brand products such as Littelfuse, Juding and Raychem.

●Basic principles

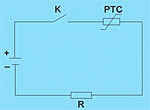

The full name of polymer PTC is "polymer positive temperature coefficient thermistor". It has excellent overcurrent protection function due to the special properties of its material. Polymer PTC is connected in series in the circuit (as shown in Figure 1). Under normal circumstances, it is in a low resistance state and the working current can pass smoothly; when an abnormally large current occurs in the circuit, its impedance increases rapidly (it is in a high resistance state) ), effectively limiting the passage of large current and protecting the circuit from damage (Figure 2). When the fault current is eliminated, the resistance of the polymer PTC drops rapidly and returns to the low resistance state.

●Selection guide

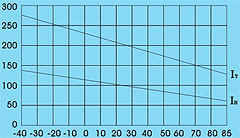

Using polymer PTC is safe and convenient, which is a win-win strategy. When selecting, first consider that the working voltage should be less than or equal to the maximum voltage that the polymer PTC can operate; secondly, match the working current. The working current (IH) listed in the specification refers to the current value when the working environment temperature is 25°C. , if the actual working environment temperature is different from it, the temperature and current reduction factors should also be considered. Please refer to Figure 3 for details. Finally, the installation method (such as plug-in, light sheet insertion) must be considered. For other technical indicators, please refer to the specification sheet. If there are special circumstances, please contact our company directly to see if special processing is possible.

Figure 1 Figure 2

Overview of over-current protection chip: Over-current protection chip is specially used to prevent battery over-temperature caused by excessive charging. Battery over-temperature is a major concern of battery pack designers. Although there are overvoltage and overcurrent detection safety protection circuits in the lithium battery pack (including integrated circuits and semiconductor circuits that may malfunction in the event of excessive electrostatic discharge, excessive temperature, or short circuit), the voltage protection circuit If the battery fails and does not have temperature protection, the battery will generate excessive heat when overcharged or overcharged, causing the battery to rupture, leak, smoke, or even burn.

Huaju Company has launched a new type of strip-shaped over-current protection sheet. Compared with previous products, the resistance is lower. This device can play the role of over-current protection and over-temperature protection at the same time. It is specially designed to reduce the impedance of the battery pack and meet the requirement of longer working time. Designed for portable electronic products requiring. Especially suitable for secondary (rechargeable) batteries that are more sensitive to temperature, such as lithium-ion and nickel-metal hydride.

The battery overcurrent protection chip is connected in series with the original cells in the battery pack. Regardless of whether the temperature rise is caused by a short circuit or overcharging, the device can play a protective role without the need for a thermal fuse or bimetal circuit breaker. This strip-shaped device uses nickel as the pin, is small and thin, and can be directly welded to the original battery, saving space and reducing installation costs.

1. Strip battery overcurrent protection sheet

●RFS series overcurrent protection sheet product dimensions

Model

A B C D1 D2 E MIN MAX MIN MAX MIN MAX MIN MIN MIN MAX RFS-070 19.9 22.1 4.9 5.2 0.7 1.2 5.5 5.5 3.9 4.1 RFS-120 19.9 22.1 4.9 5.2 0.6 1.0 5.5 5.5 3.9 4.1 RFS-175 20.9 23.1 4.9 5.2 0.6 1.0 4.1 4.1 3.9 4.1 RFS-200 21.3 23.4 10.2 11.0 0.5 1.1 5.0 5.0 4.8 5.4 RFS-350 28.4 31.8 13.0 13.5 0.5 1.1 6.3 6.3 6.0 6.6 RFS-420 30.6 32.4 12.9 13.6 0.5 1.1 5.0 5.0 6.0 6.7 ●Electrical characteristics of RFS series overcurrent protection chip (25℃)

Model

Ih

It

Trip Time

Vmax

Imax

Rmin

Rmax

Pdmax

A

A

A

S

V

A

Ω

Ω

W

RFS-070 0.70 1.45 3.5 5.0 15 100 0.100 0.200 0.7 RFS-120 1.20 2.70 6.0 5.0 15 100 0.085 0.16 0.8 RFS-175 1.75 3.80 8.75 5.0 15 100 0.050 0.090 0.9 RFS-200 2.00 4.40 10.0 4.0 30 100 0.30 0.60 1.6 RFS-350 3.5 6.3 20 3.0 30 100 0.017 0.031 1.9 RFS-420 4.2 7.6 20 6.0 30 100 0.012 0.024 2.2 ●LV series overcurrent protection film product dimensions

Model

A B C D1 D2 E MIN MAX MIN MAX MIN MAX MIN MIN MIN MAX LV110 23.6 25.6 2.7 2.9 - 0.7 7.0 7.0 2.3 2.5 LV170 20.9 22.9 4.9 5.3 0.5 0.8 6.0 6.0 3.9 4.1 LV175 21.2 23.2 3.5 3.7 - 0.7 5.6 5.6 2.9 3.1 LV210 20.9 23.1 4.9 5.3 0.6 0.8 4.1 4.1 3.9 4.1 LV220 21.1 23.3 3.5 3.9 0.6 0.8 5.1 5.1 2.9 3.1 LV230 23.9 23.1 4.9 5.1 - 0.7 4.1 4.1 3.9 4.1 LV270 20.9 23.1 4.9 5.3 0.6 0.8 4.1 4.1 3.9 4.1 ●Electrical characteristics of LV series overcurrent protection chip (25℃)

Model

Ih

It

Trip Time

Vmax

Imax

Rmin

Rmax

Pdmax

A

A

A

S

V

A

Ω

Ω

W

LV110 1.1 2.7 7.00 5.0 16 100 0.038 0.070 0.7 LV170 1.7 3.4 8.50 5.0 16 100 0.030 0.052 0.7 LV175 1.75 3.6 8.75 5.0 16 100 0.029 0.051 0.8 LV210 2.1 4.7 10.0 5.0 16 100 0.018 0.030 1.2 LV220 2.2 5.3 11.0 5.0 16 60 0.017 0.029 0.8 LV230 2.3 5.0 10.0 5.0 12 100 0.012 0.018 1.4 LV270 2.7 6.5 13.5 5.0 16 60 0.012 0.018 1.2 ●LR series overcurrent protection sheet size

Model

A B C D1 D2 E MIN MAX MIN MAX MIN MAX MIN MIN MIN MAX LR-070 19.0 22.0 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-100 20.0 23.0 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-170 16.0 18.0 4.9 5.2 0.6 0.8 5.0 5.0 3.9 4.1 LR-175 20.0 23.0 3.5 3.8 0.6 0.8 5.0 5.0 2.9 3.1 LR-180 23.0 25.0 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-190 20.0 22.5 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-200 20.0 23.0 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-260 20.0 23.0 4.9 5.2 0.6 1.0 5.0 5.0 3.9 4.1 LR-300 28.0 31.8 6.9 7.5 0.6 1.0 6.0 6.0 4.9 5.1 LR-350 28.0 31.8 6.9 7.5 0.6 1.0 6.0 6.0 4.9 5.1 LR-380 28.0 31.8 6.9 7.5 0.6 1.0 6.0 6.0 4.9 5.1 LR-450 25.0 28.0 10.0 15.5 0.6 1.0 5.0 5.0 4.9 5.1 LR-550 30.0 35.0 6.9 7.5 0.6 1.0 6.0 6.0 4.9 5.1 LR-600 28.0 30.0 6.9 14.5 0.6 1.0 6.0 6.0 5.9 6.1 LR-730 27.0 29.0 13.9 14.5 0.9 1.0 6.0 6.0 5.9 6.1 LR-900 45.0 48.0 7.5 8.5 0.9 1.3 6.0 6.0 5.9 6.1 LR-1300 61.0 66.0 9.4 10.0 0.9 1.3 6.0 6.0 5.9 6.1 LR-1410 58.0 60.0 13.4 14.0 0.9 1.3 6.0 6.0 5.9 6.1 ●Electrical characteristics of LR series overcurrent protection chip (25℃)

Model

Ih

It

Trip Time

Vmax

Imax

Rmin

Rmax

Pdmax

A

A

A

S

V

A

Ω

Ω

W

LR-070 0.70 1.45 3.5 5.0 15 100 0.100 0.200 0.70 LR-100 1.00 2.5 5.0 7.0

16 100 0.070 0.130 0.90 LR-170 1.70 3.4 8.5 5.0 16 100 0.030 0.052 0.70 LR-175 1.75 3.6 8.5 5.0 16 100 0.030 0.050 0.80 LR-180 1.8 3.8 9.0 2.9 16 100 0.040 0.050 1.0 LR-190 1.9 4.2 10.0 3.0 16 100 0.039 0.079 1.9 LR-200 2.0 4.4 10.0 4.0 16 100 0.030 0.060 1.6 LR-260 2.6 5.8 13.0 5.0 16 100 0.020 0.042 1.0 LR-300 3.0 6.3 15.0 4.0 20 100 0.015 0.031 1.7 LR-350 3.5 7.2 20.0 3.0 20 100 0.017 0.031 1.9 LR-380 3.8 8.3 19.0 5.0 20 100 0.013 0.026 1.2 LR-450 4.5 8.9 22.5 5.0 20 100 0.011 0.020 1.4 LR-550 5.5 10.5 27.5 5.0 20 100 0.009 0.016 2.0 LR-600 6.0 11.7 30.0 5.0 20 100 0.007 0.014 1.7 LR-730 7.3 14.1 30.0 5.0 20 100 0.006 0.012 1.9 LR-900 9.0 17.0 45.0 5.0 20 100 0.004 0.010 2.5 LR-1300 13.0 21.2 50.0 10.0 20 100 0.004 0.007 2.2 LR-1410 14.1 26.2 70.0 5.0 20 100 0.003 0.005 2.2 ●RFV series overcurrent protection film product dimensions

Model

A B C D1 D2 E MIN MAX MIN MAX MIN MAX MIN MIN MIN MAX RFV-110 23.6 25.6 2.7 2.9 - 0.7 7.0 7.0 2.3 2.5 RFV-170 15.4 17.5 7.0 7.4 0.5 0.8 4.0 4.0 3.9 4.1 RFV-175 21.2 23.2 3.5 3.7 - 0.7 5.6 5.6 2.9 3.1 RFV-200 20.9 23.1 4.1 4.5 - 0.8 3.0 3.0 3.9 4.1 RFV-210 20.9 23.1 4.9 5.3 0.6 0.8 4.1 4.1 3.9 4.1 RFV-240 23.8 26.2 4.9 5.3 - 0.8 3.5 3.5 3.9 4.1 ●Electrical characteristics of RFV series overcurrent protection chip products (25℃)

Model

Ih

It

Trip Time

Vmax

Imax

Rmin

Rmax

Pdmax

A

A

A

S

V

A

Ω

Ω

W

RFV-110 1.1 2.7 7.0 5.0 16 100 0.038 0.070 0.7 RFV-170 1.7 3.4 8.5 3.0 16 100 0.030 0.052 1.0 RFV-175 1.75 3.6 8.75 5.0 16 100 0.029 0.051 0.8 RFV-200 2.0 4.7 10.0 5.0 16 100 0.018 0.030 1.2 RFV-210 2.1 4.7 10.0 5.0 16 100 0.018 0.030 1.2 RFV-240 2.4 5.9 12.0 5.0 16 100 0.014 0.026 1.0 2. Round battery overcurrent protection sheet

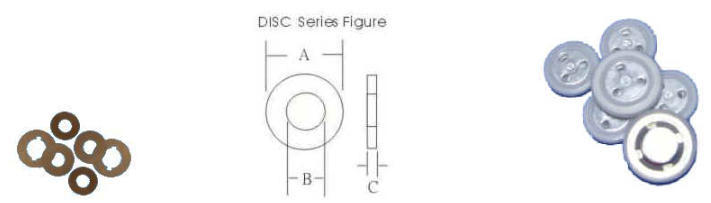

●Disc PTC product dimensions

Model

I hold

Vmax

I max

Trip Time

Rmin

Rmax

A

Vdc

A

A

T(s)

Ω

Ω

PTC-3870D

3.50

15

40

12.50

10.00

0.008

0.045

PTC-3871D 2.50

15

40

10.00

6.00

0.018

0.065

PTC-3872N 3.00

15

40

12.00

5.00

0.015

0.060

PTC-3873N 3.00

15

40

10.00

5.00

0.017

0.065

PTC-3874N 2.50

15

40

10.00

5.00

0.014

0.060

PTC-3875N 2.80

15

40

5.00

80.00

0.015

0.060

PTC-3876N 1.20

15

40

10.00

10.00

0.015

0.078

PTC-3877N 1.20

15

40

10.00

5.00

0.025

0.072

PTC-3878N 1.40

15

40

8.00

1.00

0.040

0.100

PTC-3879N 2.20

15

40

10.00

5.00

0.005

0.055

●Disc PTC overcurrent protection chip product electrical characteristics (25℃)

Model

A

B

C

Electrode Material

Electrode material

MAX

MAX

MAX

PTC-3870D

14.15

7.55

0.36

Ni/Cu

PTC-3871D 15.15

9.05

0.36

Ni/Cu

PTC-3872N 16.10

10.15

0.38

Ni

PTC-3873N 16.33

11.05

0.35

Ni

PTC-3874N 16.10

10.15

0.36

Ni

PTC-3875N 14.45

6.35

0.38

Ni

PTC-3876N 15.45

9.05

0.36

Ni

PTC-3877N 15.80

9.05

0.34

Ni

PTC-3878N 11.75

5.55

0.36

Ni

PTC-3879N 16.05

8.05

0.36

Ni

Key words:

PPTC overcurrent protection sheet for circular batteries

Product inquiry

Note: Please leave your contact information and our professionals will contact you as soon as possible!